Is Cranfield is the right place for you? We host and attend a range of events, virtually, on campus and around the world!

Ways to meet us

Overview

- Start dateFull-time: October. Part-time: October (other start dates can be discussed with the course director)

- DurationMSc: full-time one year, part-time up to three years; PgDip: full-time up to one year, part-time two years; PgCert: full-time up to one year, part-time two years

- DeliveryTaught modules 80 credits, group project 40 credits, individual project 60 credits (total MSc 180 credits)

- QualificationMSc, PgDip, PgCert

- Study typeFull-time / Part-time

- CampusCranfield campus

Who is it for?

This course is suitable for graduates with science, applied science, maths, engineering or related degrees keen to pursue careers in the development or exploitation of materials; graduates currently working in industry keen to extend their qualifications; individuals wishing to start/progress their career; or individuals with other qualifications who possess considerable relevant experience.

Why this course?

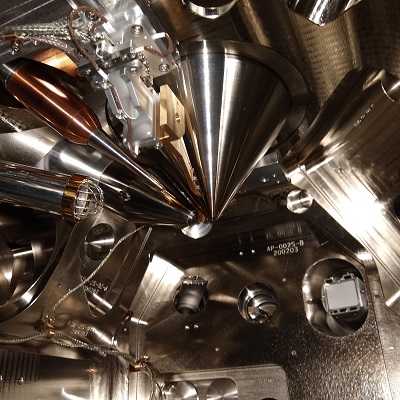

Cranfield University has an enviable track record in the development and application of advanced materials and their associated processing and manufacturing technologies. This spans from our surface engineering coatings used to increase the operating temperature of gas turbine engines to the development of composite material structures for application in some of the world’s most exotic super cars. Our research and commercial work with industry shape our taught programmes (lectures and projects), where our academic teams are leading in their fields.

This course equips students with the knowledge and skills to solve a wide range of engineering challenges. The progressive subject of additive manufacturing is introduced and investigated in the Advanced Materials Processing Technologies module. The quest for stronger, lighter, more durable materials is discussed in the Composites Design, Manufacturing and Applications module and the Materials Selection and Design module. Our ability to modify materials to function in aggressive environments is presented in the Engineering of Nano and Functional Materials module and the Industrial Applications of Advanced Materials module. Every engineer needs to recognise that resources are finite, and the impact materials and manufacturing can have on the ecosystem. The Materials for a Net Zero Future module identifies some of the current challenges and some strategies to avoid catastrophe.

Our research centres in Composites and Advanced Materials, Surface Engineering and Precision and Welding and Additive Manufacturing are integrated into the delivery of the course through our research and teaching teams, who are passionate in sharing their knowledge and experience in materials.

The group and individual projects are often sponsored by industry giving you highly relevant context to your studies and practical work. With access to many of our unique laboratories and facilities, working alongside our leading research teams Cranfield is the perfect environment to launch your career.

I really enjoy the labs and seeing what current research is going on. I also enjoy when we have several different lecturers delivering a module as they all have their individual expertise. We get an in-depth look at these areas from someone passionate about their work and research. I feel confident in my knowledge and understanding. I have become very interested in research and development and this MSc puts me on track for that area of industry.

The Advanced Materials course opened up a lot of opportunities for me and as a direct result of my thesis project, my visibility across the automotive industries increased. I also had the chance to publish papers and present as a speaker at Automotive related conferences.

We were very lucky to be able to work so closely with Airbus as our industrial supervisor on our group project. We had regular communications with them, face-to face and via email and they gave a lot of feedback too so we were very fortunate for that.

The module I enjoyed the most was probably the Failure of Materials and Structures. It was a very technical module involving maths, mechanical behaviours but also materials knowledge and environmental effects. It also includes different methods of analysis as lab experiments (strain-stress tests) and computations on failure simulations. Being very technical and involving a wide variety of different phenomena, this module was for me one of the most interesting ones.

Informed by industry

Our courses are designed to meet the training needs of industry and have a strong input from experts in their sector. Our advisory panel has members from well-known companies such as AkzoNobel, GKN, Marshall ADG, NCC and Scott Bader UK. Students who have excelled have their performances recognised through course awards. The awards are provided by high-profile organisations and individuals, and are often sponsored by our industrial partners. Awards are presented on Graduation Day.

Course details

The course comprises seven assessed modules, a group project and an individual research project.

The modules include lectures, discussions, tutorials and lab demonstrations, and are assessed through practical work, reports, case studies, infographics, essays and presentations. These provide the ‘tools’ required for the group and individual projects.

Course delivery

Taught modules 80 credits, group project 40 credits, individual project 60 credits (total MSc 180 credits)

Group project

The group project experience is highly valued by both students and prospective employers where teams of students develop both technical and team working skills to solve an industrial problem. Part-time students may be able to prepare a dissertation on an agreed topic if a group project activity is not suitable for their study circumstances.

Industrially orientated, our team projects have support from external organisations. As a result of external engagement, Cranfield students enjoy a high degree of success when it comes to securing employment.

Examples of group projects include:

- Self-lubricating coatings for novel power dense rotary engine: sponsored by Enigma England, the project looked to provide an innovative materials solution to allow a dry lubrication system for their rotary engine. Self-lubricating coatings were investigated, and characterisation tests completed to determine tribological properties alongside the simulation of the mechanical environment in the engine. Microscopy and SEM imaging were also used by the students to observe the material surfaces. The project concluded with a recommendation for the rotor (hard anodised aluminium 2024 coated with PTFE ) and the chamber (AMC4632) of the engine.

- Solar desalination – off-grid water treatment technology: this innovative British Council sponsored project looks to help provide an innovative solution to a lack of clean water supplies in the hottest regions on Earth. The student team developed a low-cost desalination system that’s easy to maintain and can be disassembled for transportation. The materials innovation incorporated Fresnel lenses into the desalination system.

“My group project was on adding graphene to polymers to enhance their properties. This project was mainly lab work. We worked on extruding polymers that contain a certain percentage of graphene. We optimised the graphene percentage inside the polymers using mechanical testing. We also made our own samples using polymer injection moulding.” - Advanced Materials MSc graduate, Noor Ghadarah.

Individual project

Students select the individual project in consultation with the Course Director. The individual project provides students with the opportunity to demonstrate their ability to carry out independent research, think and work in an original way, contribute to knowledge and overcome genuine problems.

Examples of individual projects include:

- Material selection of a polymer for high-temperature automotive connectors;

- Investigation of plasma cleaning process for wire+arc additive manufacturing.

Modules

Keeping our courses up-to-date and current requires constant innovation and change. The modules we offer reflect the needs of business and industry and the research interests of our staff and, as a result, may change or be withdrawn due to research developments, legislation changes or for a variety of other reasons. Changes may also be designed to improve the student learning experience or to respond to feedback from students, external examiners, accreditation bodies and industrial advisory panels.

To give you a taster, we have listed the compulsory and elective (where applicable) modules which are currently affiliated with this course. All modules are indicative only, and may be subject to change for your year of entry.

Course modules

Compulsory modules

All the modules in the following list need to be taken as part of this course.

Industrial Applications Of Advanced Materials

| Aim |

|

|---|---|

| Syllabus |

Mechanics of materials – strength, stiffness, hardness, corrosion, fatigue. Comparison across all material classes (metals, ceramics, polymers Impact of processing and microstructure (manufacturing routes) Functional properties of materials including thermal electric magnetic, optical, biocompatibility. Requirements and applications for emerging materials in ICT, energy and mobility, life sciences, healthcare, cosmetics, food, consumer goods, and manufacturing. Industrial cases studies demonstrating how and where these materials have been applied in real life applications. Sustainability implications of materials selection regarding effects on processing, usage and end-of-life in the context of energy, environmental hazards, labour, recycling, etc with a link to UNSDGs |

| Intended learning outcomes |

On successful completion of this module you should be able to:

|

Advanced Materials Processing Technologies

| Aim |

|

|---|---|

| Syllabus |

|

| Intended learning outcomes |

On successful completion of this module you should be able to: 2. Examine the relationships between material properties, processing conditions, metrology and performance. 3. Design appropriate manufacturing routes and post manufacturing treatments for producing products with required properties [stiffness, hardness, toughness, strength, corrosion resistance etc]. 4. Compare and contrast the processes used in additive manufacturing for a range of materials and applications. 5. Evaluate strategies towards sustainable manufacturing (management of resources). |

Materials Selection and Design

| Aim |

|

|---|---|

| Syllabus |

|

| Intended learning outcomes |

On successful completion of this module you should be able to:

|

Engineering with Nano and Functional Materials

| Aim |

|

|---|---|

| Syllabus |

|

| Intended learning outcomes |

On successful completion of this module you should be able to: 2. Compare and contrast across the range of available nanomaterials (0D, 1D, 2D and 3D). 3. Investigate opportunities and challenges to use of nanomaterials. 4. Appraise multi-functional nanomaterials. |

Composites Design, Manufacturing and Applications

| Aim |

|

|---|---|

| Syllabus |

|

| Intended learning outcomes |

On successful completion of this module you should be able to: 2. Justify appropriate manufacturing techniques for a wide range of industrial, automotive and aircraft composite structures. 3. Assess current areas of technology development for composites processing. 4. Examine how materials selection, structural load and strain estimation, laminate design and manufacturing and assembly process definition influence the design process. 5. Evaluate performance-cost balance implications of materials and process choice. |

Materials for a Net Zero Future

| Aim |

|

|---|---|

| Syllabus |

|

| Intended learning outcomes |

On successful completion of this module you should be able to: 2. Appraise the current technologies targeting reducing CO2 emissions, identifying challenges and benefits. 3. Compare and contrast the impact of using alternative materials and alternative energy sources to meet a net zero CO2 emission target. 4. Apply and examine fundamental understanding of life cycle assessments to identify the activities which produce significant CO2 emissions [materials extraction, manufacture, transport, storage, use, end of life]. |

Modelling for Materials

| Aim |

|

|---|---|

| Syllabus |

|

| Intended learning outcomes |

On successful completion of this module you should be able to: 2. Compare and contrast across the range of available nanomaterials (0D, 1D, 2D and 3D). 3. Investigate opportunities and challenges to use of nanomaterials. 4. Appraise multi-functional nanomaterials. |

Teaching team

You will be taught by industry-active research academics from Cranfield with an established track record, supported by visiting lecturers from industry. To ensure the programme is aligned to industry needs, the course is directed by an Industrial Advisory Committee. The Course Director for this programme is Dr David Ayre, the Admissions Tutor for this programme is Dr Sameer Rahatekar. This course is supported by Professor Krzysztof Koziol, Head of Enhanced Composites and Structures Centre.

Accreditation

The Advanced Materials: Engineering and Industrial Applications MSc is a new course introduced in September 2024 and accreditation, similar to that achieved for the previous Advanced Materials MSc course, is currently being sought (2024/2025). The previous Advanced Materials MSc course is accredited by the Institution of Mechanical Engineers (IMechE), the Royal Aeronautical Society (RAeS), The Welding Institute (TWI), the Institute of Materials, Minerals and Mining (IOM3), and the Institution of Engineering & Technology (IET) on behalf of the Engineering Council as meeting the requirements for further learning for registration as a Chartered Engineer (CEng).

In 2019, Cranfield Manufacturing and Materials was honoured to receive a commemorative award from the Institute of Materials, Minerals and Mining (IOM3) recognising continued accreditation for over 15 years.

Your career

On completion of this MSc, graduates have a broader network of global contacts, increased opportunities for individual specialism and a wide range of careers options involving materials with responsibilities in research, development, design, engineering, consultancy and management.

Our graduates find careers with global industries alongside innovative start-ups and SMEs which have included:

- Airbus,

- Cytec Industries,

- Marshalls Aerospace,

- National Composites Centre,

- Nippon Sheet Glass Co. Ltd,

- Rolls-Royce,

- Solvay.

Some graduates prefer to stay in academia and enter into research at universities across Europe. Most continue in a career associated with engineering and materials, seeking solutions to industries' challenges across the whole spectrum of civil, electrical, energy, industrial, manufacturing and transportation activities.

Cranfield’s Career and Employability Service is dedicated to helping you meet your career aspirations. You will have access to career coaching and advice, CV development, interview practice, access to hundreds of available jobs via our Symplicity platform and opportunities to meet recruiting employers at our careers fairs. Our strong reputation and links with potential employers provide you with outstanding opportunities to secure interesting jobs and develop successful careers. Support continues after graduation and as a Cranfield alumnus, you have free life-long access to a range of career resources to help you continue your education and enhance your career.

How to apply

Click on the ‘Apply now’ button below to start your online application.

See our Application guide for information on our application process and entry requirements.