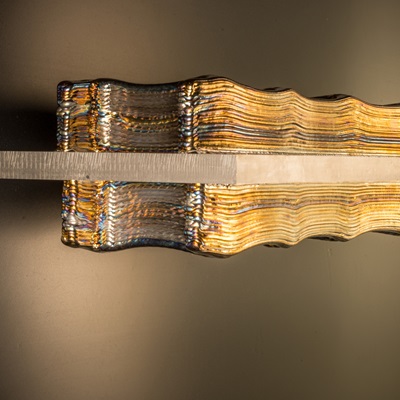

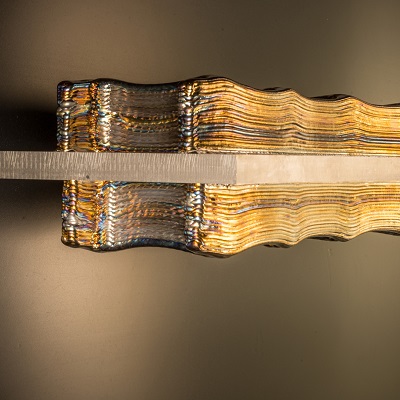

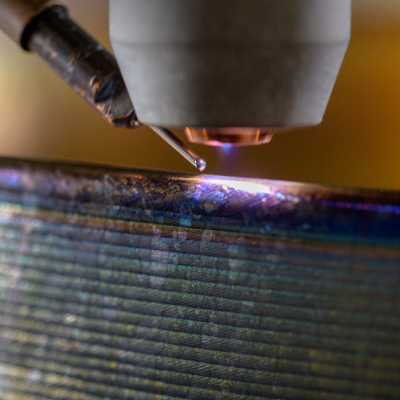

Our major areas of research are focused on metal additive manufacturing – the 3D printing of large-scale parts – and new methods of fusion joining. The research is scientifically based but industry focused.

The Centre is recognised for the impact of its research into advanced fusion methods on industry, through sponsored master’s and PhD research, and its rolling technology development programme on additive manufacturing. The WAAM programme (wire plus arc additive manufacture) aims to make the UK the leading technology provider in terms of transforming practice and creating a commercial option. Industry partners to WAAM include BAE Systems, Bombardier and Fokker.

We have had a significant role in improving practices in onshore and offshore pipeline manufacturing with industrial partners such as Hereema Marine Contractors and Technip. Our other stakeholders include UK and EU government bodies as well as partners in the aerospace (Airbus, ARA), aero-engines (Rolls-Royce), defence (Lockheed-Martin), nuclear (AWE), shipbuilding (BAE surface ship), medical (Attica) sectors, as well as among welding power source manufacturers (Air Liquide, Fronius, TPS, Lincoln).

Activities are based around a laboratory, housing a variety of laser and arc welding facilities with a large-scale material handling facility. Facilities are equipped with robots to enable automated welding and make use of the latest quantitative analysis technologies to model the weld processes necessary for making fundamental analyses.

We are the fusion process owner of the EPSRC sponsored Centre for Innovative Manufacturing in Laser which is a large consortium of industry and academia focused in increasing manufacturing productivity in UK by increasing application of laser in the sector.