The manufacturing and materials capability at Cranfield University is world leading and combines a multi-disciplinary approach that integrates design, technology and management expertise.

Over 20 PhD positions

By choosing a self-funded PhD opportunity within Cranfield Manufacturing and Materials, it will put you at the heart of a vibrant doctoral research community where you will work closely with your academic supervisor (many of whom are leading in their area of expertise).

Access is available to our impressive high-tech facilities for the duration of your research. The 2022 Research Excellence Framework (REF) has recognised 88% of Cranfield’s research as world leading or internationally excellent in its quality.

The Manufacturing Doctoral Community aims to create a research community to improve your experiences via different activities. Training is a major activity that provides hands-on and practical sessions on a range of topics, such as starting the PhD research journey, developing research methodology, systematic literature search, performing literature review and industrial field study as well as data analysis, searching the right journal with impact factor and writing journal papers and PhD thesis.

Cranfield Manufacturing and Materials is offering you the opportunity to study with us in one of the following research areas. These self-funded project areas have been developed to ensure you will be working on cutting-edge, industry-relevant research in alignment to Cranfield Manufacturing and Materials’ research strategy.

See the latest studentships in Composites

Advanced Materials Process Engineering

Manufacturing of spherical D2 filled SiO2 capsule

Hollow micro/nano spheres have been widely used with applications such as drug delivery, photocatalysis, gas sensors, lithium batteries, and solar cells. This PhD involves the fabrication of hollow spheres with large specific surface area and low density. This is a highly futuristic project, where the focus is on development of a wet chemical method to synthesise hollow spheres with size-controllable and wall thickness-controllable capability. Furthermore, the gas release rate from these hollow spheres will be tested.

Lead academic: Dr Qi Zhang

The recovery of high value-added metals from spent lithium-ion batteries

This project will develop a toolbox of ambient temperature leaching systems for manipulation and processing of elements in spent LIBs. It will understand the leaching behaviour of cathode scrap from spent LIBs and to find out the correlation between the leaching speed and recovery rate of the corresponding metals. It will also determine the conditions to ensure both high leaching efficiency and leaching selectivity will be achieved by optimised process design.

Lead academic: Dr Qi Zhang

New Materials for Anti-corrosive Protective Coatings Applications in Oils and Gas Industry

The aim of this research is to investigate the use of different innovative materials targeted for specific applications. The automotive, aerospace, electronics, oil and gas industries aims to use more green and environmental friendly materials from sustainable sources for such applications.

Lead academic: Professor Krzysztof Koziol

Advanced composite materials for energy storage and harvesting

Develop a new class of dielectric and piezoelectric composite materials based on surface engineering of commonly used piezoelectric polymers and organic or inorganic 1-D nano-materials to exhibit superior electro-mechanical response (conversion efficiency>50%; power density>100 mW), electrical properties, flexibility combined with low-cost manufacturing.

The research will lead to a new family of flexible and compressible piezoelectric materials.

Lead academic: Professor Krzysztof Koziol

Disruptive processing technologies for biomanufacturing

Bioprocessing has become one of the most strategic areas in manufacturing and is concerned with a very large number of products ranging novel pharmaceuticals and advanced therapies, food ingredients, sustainable materials and even fuels. Using Cranfield’s advanced continuous processing technology this research focuses on the development of continuous, algorithm controlled bioprocessing technologies for application to biorefineries. The project will offer opportunities to engage with the world class teams from within the lead academic’s network of collaborators.

Lead academic: Professor Harris Makatsoris

Through-life Engineering Services (TES)/IVHM

Business modelling to evaluate predictive maintenance benefits for commercial aircraft fleet level total ownership cost

Predictive maintenance is promising a step change to commercial aircraft operations. Benefits realisation depends on the business and operations approach of the airlines and leasing companies. This research aims to complete a model to simulate the dynamics of fleet total cost of ownership, part of the Cranfield Digital Aviation initiative.

Lead academic: Dr Ip-Shing Fan

Information modelling to support paperless operations for commercial aircraft through life maintenance and support

Maintenance of commercial aircraft involves a lot of papers, imposed by authorities and commercial stakeholders. This research works with industrial partners to create and validate an ontology model for aircraft through life support, and develop pre-competitive commercial demonstrations as part of the Cranfield Digital Aviation initiative.

Lead academic: Dr Ip-Shing Fan

Corrosion-sensitive multiscale fatigue modelling

Study the effects of corrosion-induced changes in composition on fatigue damage in metallic materials. We will employ multiscale models to understand the role of compositional changes on plastic deformation and inform fatigue prognosis approaches.

Lead academic: Dr Gustavo M. Castelluccio

Multiscale modelling of metallic materials after overloads

Study the mechanical response of metals after overloads by developing physics-based models informed with experiments across scales. We seek to explain why some overloads may have no noticeable effect in metals while other events can profoundly affect their mechanical response.

Lead academic: Dr Gustavo M. Castelluccio

Sensor/feature engineering for integrated vehicle health management (IVHM)

IVHM is an enabling discipline consisting of technologies to assess the reliability and failures of a product in its actual life cycle conditions to mitigate system risk. Sensor Systems and Feature Identification are important aspects of an IVHM system design. Current Sensor/Feature Engineering is mainly dependent on past failures and engineering judgements. This PhD will develop a systematic process using energy principles to identify optimum sensor(s)/feature(s) for complex engineering system failures for aerospace, automotive, rail or energy applications.

Lead academic: Dr Suresh Perinpanayagam

Advanced IVHM/data analytics for optimising manufacturing systems

Due to the pressures of modern business constraints, machine downtime can prove to be very costly for businesses, not only in terms of immediate delivery misses, but even more so in terms of long-term loss of customer satisfaction and reputation. For these reasons, having zero unplanned downtime will not only be critical, but also a necessity in the future. Integrated Vehicle Health Management (IVHM) capability can be a critical part of this journey because, by its very nature, IVHM helps detect anomalies and anticipate problems which can be used to schedule inspections, repairs, and overhauls at the most optimal times. This PhD will develop advanced IVHM/data analytics techniques for monitoring and optimising manufacturing systems.

Lead academic: Dr Suresh Perinpanayagam

Novel end-of-life prediction algorithms for batteries

Batteries are widely used in spacecraft, aircraft, and electric vehicles. Hence, an accurate prediction of the remaining useful life (RUL) is essential for these applications. Significant research has been conducted in order to get higher energy density, reduced weight and cost, longer life, or shorter recharge times. New materials and technologies are continually being explored with the goals of improving the technology and satisfying consumer requirements. The ability to precisely monitor and manage battery health will increase performance and avoid failures, such as loss of operation, reduced competency, stoppage, and even catastrophic failure. This PhD will focus on accurately predicting the end-of-life of batteries with different chemistries using model-based deep learning techniques.

Lead academic: Dr Suresh Perinpanayagam

Intelligent systems employing artificial intelligence and machine learning for complex engineering

Intelligent systems are seen as central to delivering intelligent services in business, society and private life. This can be seen from intelligent factory controls, autonomous and connected vehicles, smart energy generators, predictive medicine, etc.This PhD programme will prepare you for complex engineering problems in the the aerospace, automotive, rail, power & energy and healthcare sectors.

Lead academic: Dr Suresh Perinpanayagam

Multi-imaging sensors based automatic large parts Inspection

Current inspection methods for large parts are either contact or limited to surface detection. This project will develop the proof-of-concept for a scanner-camera-thermography based 3D inspection system that performs a complete inspection for surface and subsurface discontinuities occurring in large industrial parts in an automatic, non-destructive, intelligent and robust manner.

Lead academic: Dr Yifan Zhao

Deep learning based super resolution for non-destructive testing

Develop a deep learning based method to enhance the resolutions of images. High spatial and temporal resolution images are strongly demanded in various non-destructive testing. In many cases it is difficult to obtain them due to high cost and inherent physical constraints of sensors or bandwidth.

Lead academic: Dr Yifan Zhao

Composites

Smart multifunctional composites

Successful candidate will be working on a pioneering scientific study in a vibrant multidisciplinary team of students, researchers and staffs, and will have the opportunity of collaboration with the internationally recognised academies and industries. The PhD research aims to develop a smart composite material and structure capable of self-sensing and self-tailoring in varying operation conditions.

Lead academic: Professor Krzysztof Koziol

In-situ monitoring and toughening of composite structures

Carry out research on toughening/strengthening and in-situ monitoring of aerospace grade fibre-reinforced polymer composites structures.The aim is to develop and optimise a novel toughening and in-situ measurement technique for high performance composite. The materials, consumables and research facilities will be supplied by the industrial partners and the Centre.

Lead academic: Professor Krzysztof Koziol

Augmented reality composites assembly

Successful candidate will be working on a pioneering scientific study in a vibrant multidisciplinary team of students, researchers and staffs, and will have the opportunity of collaboration with the internationally recognised academies and industries. The PhD research aims to develop an interactive augmented reality system for reliable Composites Assembly for aerospace applications.

Lead academic: Professor Krzysztof Koziol

Advanced composite materials for energy storage and harvesting

Develop a new class of dielectric and piezoelectric composite materials based on surface engineering of commonly used piezoelectric polymers and organic or inorganic 1-D nano-materials to exhibit superior electro-mechanical response (conversion efficiency>50%; power density>100 mW), electrical properties, flexibility combined with low-cost manufacturing.

The research will lead to a new family of flexible and compressible piezoelectric materials.

Lead academic: Professor Krzysztof Koziol

Multifunctional renewable carbon fibres composites for advanced applications

Develop new renewable resources (e.g. lignin) based green precursors as well as most efficient processing techniques for the fabrication of high strength sustainable carbon fibres as well as composites thereof. Multifunctional characteristics in the composites will be introduced by incorporating other organic/inorganic functional components in the carbon fibres through suitable chemistry.

Lead academic: Professor Krzysztof Koziol

Nanocellulose based flame retardants for multifunctional composites

Develop a novel multifunctional cellulose nanocrystal (CNC) based fire retardant system (FR) for use in polymers. The CNCs will be functionalised by coating with nano-sized ceramic complex's that are expected to show improved fire resistance and mechanical properties due to charring and shielding or insulating of surface due to condensed and gaseous phase reactions initiated by nano complex and reinforcement by CNC respectively.

Lead academic: Professor Krzysztof Koziol

Advanced materials for energy storage and harvesting

The aim of this research is to investigate the use of different innovative materials targeted for specific applications. The automotive, aerospace, electronics, oil and gas industries aims to use more green and environmental friendly materials from sustainable sources for such applications.

Lead academic: Professor Krzysztof Koziol

Additive manufacturing of polymer composites for multifunctional materials

Carry out fundamental research on using additive manufacturing to print thermoplastics and biodegradable composites from different nanomaterials including cellulose nanocrystals(naturally abundant materials extracted from waste agricultural and forest products) for structural, energy storage and biomedical applications.

Lead academic: Professor Krzysztof Koziol

Nanocellulose based multifunctional composites

The aim of this research is to investigate the use of different innovative materials targeted for specific applications. The automotive, aerospace, electronics, oil and gas industries aims to use more green and environmental friendly materials from sustainable sources for such applications.

Lead academic: Professor Krzysztof Koziol

Graphene/nanoparticles reinforced multiscale carbon/glass composites for aerospace and automobile engineering

Fibre reinforced composites have excellent in plane strength and stiffness and are being used in increasing quantities in aerospace, sports, automotive and wind turbine blade industries. However fibre reinforced composites are weak in their through thickness direction. In this project, the PhD student will develop new generation of multi-scale composites using graphene/nanoparticles reinforcement in glass/carbon epoxy composites to increase the delamination resistance. We will work in collaboration with nanomaterials manufacturing industries as well as composites manufacturing industries to explore the industrial application of this project.

Lead Academic: Dr Sameer Rahatekar

Natural polymers based functional textiles for engineering and biological applications

This project aims to manufacture functional textiles from renewable/natural polymers such as cellulose, chitin, alginate, chitosan which derived from most abundant natural resources like agricultural biomass and sea food waste (crab shell, shrimp shells etc.). The functional textiles will be used for eco-friendly and renewable textiles/clothing, antimicrobial clothing, textiles for tissue regeneration. As a part of this project, we aim to use ionic liquids as a common solvent for dissolving biopolymer (such as cellulose) and polyaniline to produce electrically conducting textile fibres using wet spinning and electrospinning process. Such a textile fibre can be used in a smart shirt which can measure the body temperature and heart rate of a patient [3] or as a soft biocompatible electrode for stimulation of neurons. We will also explore adding natural products such as curcumin (extract from turmeric), oregano oil which is shown to be effective in antimicrobial and anti-cancerous properties to develop bandage for anti-microbial and potentially help increase the immune response for fighting cancerous cells.

Lead Academic: Dr Sameer Rahatekar

Sustainable composites for manufacturing wind turbine blades

In this project we will develop a novel manufacturing process for recycled carbon/glass fibres as well as renewable fibres like cellulose, jute, flax or bamboo to produce high performance, low cost and lightweight composites for wind turbine blades. This process will deliver high stiffness/strength composites with superior in plane properties due to continuous nature of fibres, high toughness and through thickness properties due to through thickness reinforcement. We will work in collaboration with fibre recycling industries and natural fibre industries to get the recycled and renewable fibres. The Enhanced Composites and Structures Centre at Cranfield University has excellent composites manufacturing facilities like resin transfer moulding, resin infusion as well as vacuum bagging and high pressure autoclave curing to produce a high performance composite product for wind turbine blades. The low cost and high performance sustainable composites wind turbine blades will be have great impact in renewable energy industry to offer a low cost renewable energy solution.

Lead Academic: Dr Sameer Rahatekar

Surface Engineering and Precision

Material degradation study of energy storage materials for renewable technologies

Lead Academic: Dr Adnan Syed

Material degradation study of heat-exchanger materials and coatings for renewable energy

Lead Academic: Dr Adnan Syed

Hot corrosion studies of gas turbine alloy materials

Lead Academic: Dr Adnan Syed

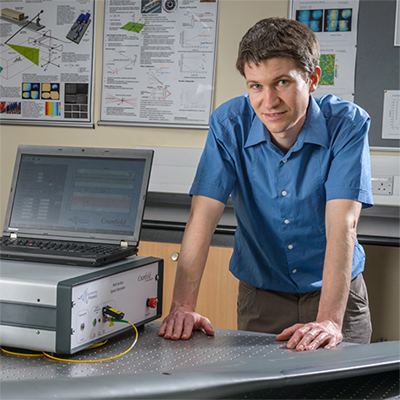

There are only three or four groups in the world where interesting work is going on in my specialist area and Cranfield is one of them.

Thomas Kissinger, Research Fellow