The Thermal Management Systems Facility (TMSF) provides opportunity to test a wide range of low to mid-TRL integrated thermal management systems, generating high quality test data for model validation.

The facility is designed to be ‘plug and play’ and support rapid assembly, test and disassembly of a wide range of integrated thermal management systems. Offering potential for engine oil and fuel systems representative of civil, defence and marine products to be operate simultaneously alongside new technologies for heat transfer and autonomous control.

The facility features:

- Two 5000L Fuel tanks

- Two 1000L Oil tanks

Fluid conditioning plant to allow

- Heating to 200°C via a 450kw hot oil system

- Cooling to ambient via a 500kw water cooling system

- Chilling to -30°C via a 60kw Chilling system

- Oil tank pre-heating via 60kw Oil heating system

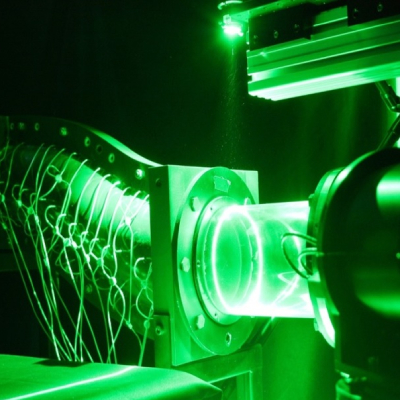

The facility houses a standalone Fuel Rig for driving large engine fuel pumps at representative conditions supplied by either the rigs own 1000L tank or the facility 5000L tanks, giving the capability of testing with small batches of new or novel fuels. The rig features:

- Fuel at up to 10bar, -30°C - 180°C

- Turbine Oil at up to 10 bar, 20°C - 180°C

- 315kw Atex Rig Motor Drive up to ~10,000 rpm

- Auxiliary Motor Drive up to ~10,000 rpm

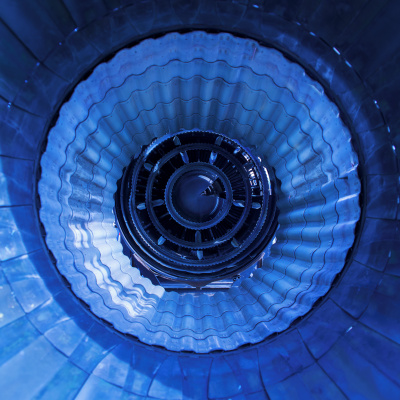

The other side of the facility is home to a 40m3 Environmental Chamber for running experiments at controlled temperatures between -40°C and +120°C. The chamber can be supplied with fluids from across the facility allowing for a varied range of testing to take place within. The conditioned fluid has allowed the facility to carry out fuel testing such as Icing Snowshower tests and fuel Coking. The supplies to the chamber include:

- -40°C to +120°C

- Fuel at up to 10 bar, -30°C - 180°C

- Turbine Oil at up to 10 bar, 20°C-180°C

- Heating oil – Paratherm NF @ up to 200°C

- Air – 10 bar

- Cooling water @ 17°C

- Chilled fluid supply down to -30°C

- The chamber has two motor drives (315kw and 110kw) capable of up to 10,000rpm in order to run fuel/oil pumps within the chamber