- Dates2019-2023

- SponsorHardide Coatings

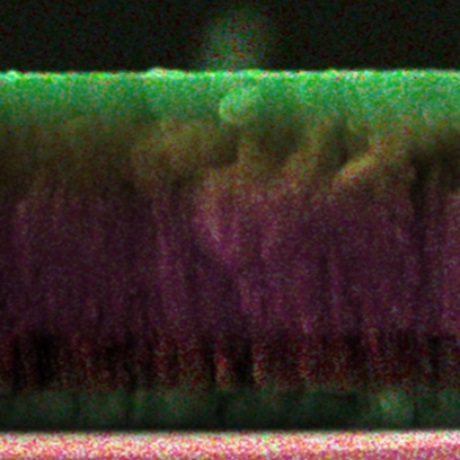

Modern engineering components often operate in extremely harsh conditions throughout their operating lifetime. Protective hard coatings are typically applied on the surface of these components to prolong their service life and to minimise the likelihood of catastrophic failure. Chemical vapour deposited tungsten carbide in tungsten matrix (WC/W) coatings are promising due to their superlative hardness and wear resistance. These coatings also eliminate the use of toxic and environmentally hazardous hexavalent precursors, such as those for existing hard chromium/cadmium plating.

Together with our sponsoring partner, Hardide Coatings, we investigated and developed methods to enable precision surface finishing of WC/W coatings. We explored a wide variety contact and non-contact processes, ranging from vibratory polishing and diamond turning to electropolishing and electrical discharge machining, to identify the effectiveness of each process and to optimise the processing parameters. Our approach and analysis offer insights into surface finishing of hard coatings and other difficult to process materials for the benefit of many engineering applications.

Progress update

Our findings to date on surface finishing of WC/W coatings can be found on the following web pages: