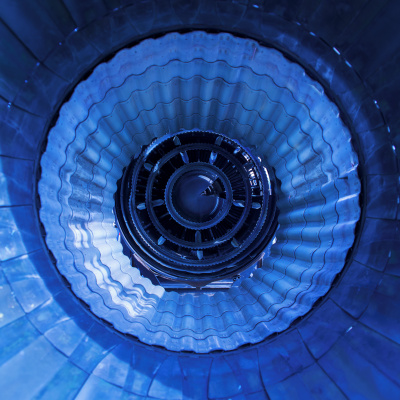

The UTC has built and commissioned a trans-critical pack as a reliable industrial-scale source of CO2 at supercritical state. It is the first one in the UK ever to be designed and operated specifically for purposes other than refrigeration. The work has already provided new knowledge on the handling of CO2 as a working fluid, on the requirements for leak detection systems, the characteristics of the inventory control system, heat exchanger design, and overall steady-state and transient control. The use of the facility to test equipment for CO2 was also considered during the design phase, so that further value could be extracted.

The knowledge gained by the team and existing hardware can be applied to the design and testing of various future aero systems such as aircraft cabin ECS, thermal management control and/or power generation. The rig can offer the following test conditions:

- Low pressure side: max pressure 50 bar

- Intermediate pressure side: max pressure 60 bar

- High pressure side: max pressure 120 bar

- Compression power: 90 kW

- SWEP evaporator heat load: 90 kW

- Gas Cooler load: 125 kW

- System designed and tested to operate at 15oC ambient temperature but could be operated between 0 and 45oC theoretically.

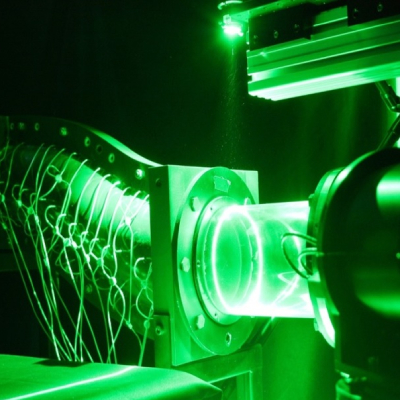

Recently the UTC completed the retrofit of the CO2 rig increasing its measurement capabilities by 230% (pressure and temperature) and enabling the relocation of the Coriolis flowmeter at the discharge of the pack. A customized data acquisition platform developed in LabVIEW™, offers measuring methods capable of capturing data for the future validation of models in steady-state and specific ranges of transient up to 250 kHz. Commissioning activities have been performed to guarantee the safe and optimal performance of the test rig in Test House 205A. The following milestones have been achieved:

- Operational test in subcritical mode with subsequent step changes in the evaporator load (between 2.5 and 5.5 lps of water) targeting 55 and 65 barg in the high-pressure side.

- Operational test in transcritical mode with subsequent step changes in the evaporator load (between 2.5 and 5.5 lps of water) targeting 85 and 95 barg in the high-pressure side.

- Full characterization of the liquid expansion valve E3V-65C.