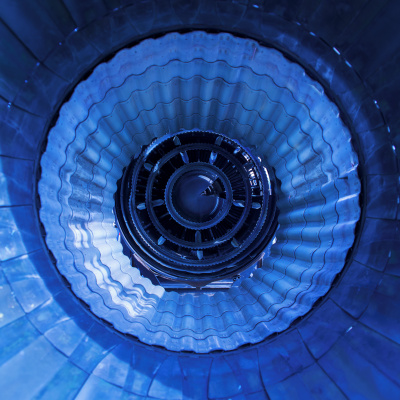

The Thermal Power and Propulsion MSc Course offers a unique opportunity for its course members to engage with the overhaul process of small gas turbines.

Gas turbine engines are used extensively in air, land and sea applications. They are very expensive equipment (a civil aircraft gas turbine will cost 3-5 times its weight in silver) reflecting the knowledge and technology that they encompass. Their components need to be designed and made with great precision to safeguard their performance. It is this precision and attention to detail that has made their operation very safe. From time to time these machines degrade and they need to be overhauled. The overhaul process is very expensive, so it is very common that all the overhauls in the life of a gas turbine cost more than the original purchase price. The overhaul process among other things, requires great attention to quality and continuous and detailed inspections. The Thermal Power and Propulsion MSc course offers an opportunity to its course members to engage with this overhaul process.

In the Cranfield Gas Turbine Laboratories (an 8000m2 site with 14 testbeds) there is a dedicated test house that offers MSc candidates a flavour of a ‘simulated’ overhaul group activity. This encompasses experiencing;

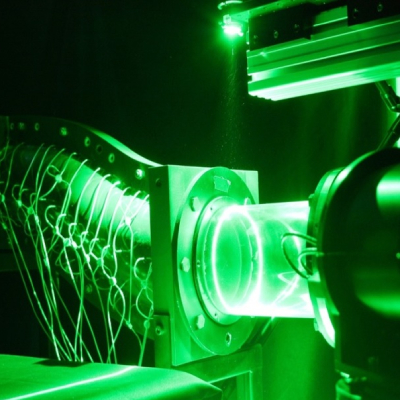

- stripping elements of a gas turbine,

- merging theoretical aspects with the practical challenges of handling a gas turbine in person,

- tool handling and the management process needed in a place where many operators work simultaneously,

- disassembly and reassembly of key components through the same procedures performed in industry,

- the safety and quality processes underpinning gas turbine operations,

- the interaction with other technical experts in the process.