Through-life engineering services address the needs of high-value products and systems from conceptual design all the way to end of life.

We concentrate on research and education in three key areas: asset management, condition monitoring and damage tolerance.

The key stages of lifecycle where we focus are:

- Design - preparing for long, cost effective system life and feeding back operational experience

- Life extension - justifying reliable decisions to keep using high-value equipment

- Planning - tackling optimisation, no-fault-found and obsolescence

- Preventive approaches - avoiding serious failure by sensing, diagnostics and prognostics.

About our research

We work in partnership with industry to examine important challenges and provide solutions that add value. We analyse commercial data to search for patterns and improve information and decision making; some of our research is with people, to establish best practices; we simulate and model systems to predict behaviour in mechanical and electronic devices; and we test physical degradation in components and materials, building novel sensors and test machines. Our applications are found in aerospace, defence, transport, manufacturing, agriculture, utilities, and facilities management.

The Centre for Life-cycle Engineering and Management undertakes a range of activities with its partners, concentrating on problem-solving, R&D, training, and education. Our aim is to help add value, by:

• Developing new solutions with the application of technology

• Developing people for the management of change and the introduction of new systems and technologies

• Helping the decision-making processes through the life of high-value products and systems.

Our facilities

We have a range of laboratory facilities to support our work. These include:

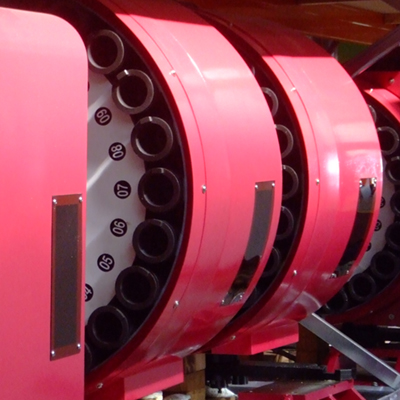

• Controlled degradation and test facilities: temperature-controlled chamber for thermal stress; accelerated gear test rigs for wear and root cracking; no-fault-found testing; vibration fault simulator; cyclic and dynamic mechanical test up to 1MN

• New technique development: robot-automated active thermography; embedded fibre-optic strain sensing

• System-level test environments: smart grid development; fuel tank structures and systems rigs; unmanned air vehicle.

Our measurement systems include vibration, strain, lubricant sampling, acoustic emissions, active pulse thermography, fibre optics and laser techniques. We also develop new measurement and processing techniques for hard-to-reach problems which need remote and unmanned autonomous solutions.

Working with us

We work with businesses in long-term partnerships and shorter-term projects.

Clients and partners

Companies repeatedly work with us, to develop their people and to create new solutions to challenging problems. Our partnerships have worked on design, monitoring, diagnostics, prognostics and life extension for industries as diverse as aircraft engines, railway infrastructure, smart grids, fuel tanks and systems, gearboxes, wind turbines and agricultural systems.

Our worked has helped to reduce waste, improve reliability and availability, and to re-validate high value components and systems for further use.

We have major partnerships in aerospace such as the Boeing Integrated Vehicle Health Management Centre. The Centre for Innovative Manufacturing in Through-life Engineering Services is supported by core sponsors BAE Systems, Bombardier Transportation UK, Rolls-Royce, and the Ministry of Defence.

Recent and current contracts include:

• Gear and sensor testing for QinetiQ

• Integrated through-life support for Network Rail, Schlumberger and Sellafield Ltd

• Materials and surface treatment testing for Alcoa, Airbus, the Civil Aviation Authority, International Paint

• Smart grids distribution automation with Western Power Distribution

• Systems development for Alstom Transport.

Our public funding clients include:

• Engineering and Physical Sciences Research Council (ESPRC)

• European Commission

• Northamptonshire County Council

• Technology Strategy Board.