- For the first time, a laser-powered 3D metal printer - the size of a microwave – has been taken to the International Space Station (ISS)

- Cranfield University worked with an international team to develop the first metal 3D printer, which launched to the ISS on January 30

- Astronauts and ground engineers will study how the absence of gravity impacts the melting of metal and the quality of 3D printed components

- The Metal3D five-year project is led by Airbus Defence and Space, working in partnership with Cranfield University, AddUp and Highftech

Cranfield University is a collaborative partner in an international project which involves sending a custom-designed 3D metal printer powered by lasers to the ISS. The goal is to gain insights into how microgravity influences its functionality.

Scientists believe that in the future, the ability to print 3D metal parts using Additive Manufacturing (AM) on board the ISS would allow for the speedy replacement of components or manufacturing of new ones. This would avoid the costly and time-consuming current approach of transporting physical parts to space.

3D metal printers fuelled by high-powered lasers have never been tested in a space environment before, and scientists will be examining data from this test to understand how the process and the metal is affected by the microgravity environment.

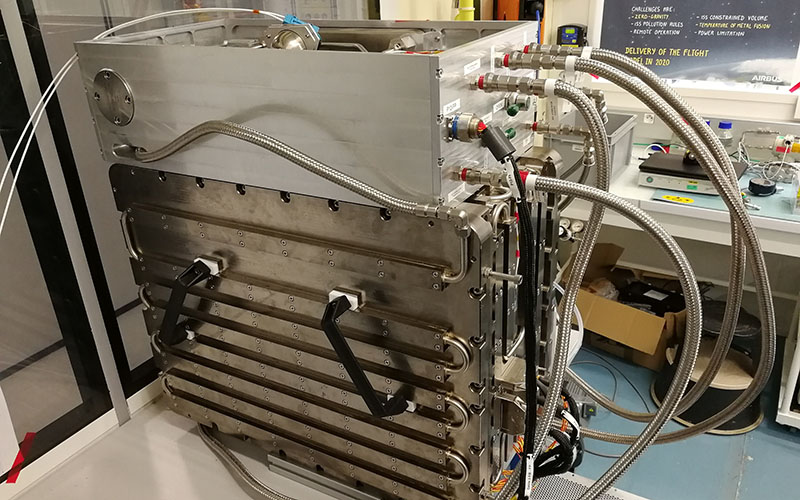

The 3D printer was taken to the ISS as part of the Cygnus NG-20 mission from Cape Canaveral in the USA. Resembling a metal box and weighing 300kg, it was transported in parts and then reassembled on board by astronauts.

Academics at Cranfield were involved in designing the printer’s melting process and hardware, as well as its laser source, delivery optics, feedstock storage and feeding system. Manufacturing experts needed to take into account the need to avoid risk factors such as heat transfer. Another challenge was the low power availability, which required an efficient process in order to melt metals.

Dr Wojciech Suder, Senior Lecturer in Laser Processing and Additive Manufacturing in Cranfield University’s Welding and Additive Manufacturing Centre, led on the design for the printer.

“We’ve measured the effect of gravity on liquids in space before,” Dr Suder said. “But we have not done this when printing components from liquid metal form because of the high temperatures involved.

“Because of that, our task was to design a printer which can be thermally neutral, and also can’t emit heat or radiation onto the ISS either. This meant it had to meet lots of requirements, in addition to being fully autonomous.

“It was quite a challenge, but one we have successfully completed. Now it’s a case of waiting for the samples to return and examining them.

“The purpose is to see the effect of microgravity on 3D metal printing. If we can understand this more, we can find out how to best use this technology in space in the future.”

The funding for ESA is made possible through investment from the UK Space Agency.

Andrew Kuh, Exploration Technology Manager at the UK Space Agency, said: “Developing efficient technologies that reduce our reliance on the costly and time-consuming transfer of materials from Earth is crucial to allow us to travel further into space for longer.

“Metal printing in space is notoriously challenging, owing to the energy

and materials required, but this innovative concept could make a huge

difference to our ability to maintain spacecraft.

“Cranfield’s contribution demonstrates how important UK skills and expertise

are to global space exploration. We look forward to following the next steps

of this fascinating technology.”

The Metal3D five-year project was led by Airbus Defence and Space, working in partnership with Cranfield University, as well as AddUp and Highftech, and was commissioned by the European Space Agency (ESA)