The nanoindentation and nanohardness testing facility is part of the Centre for Photoanalysis and Photomanipulation of Materials, which was established by SRIF funding initiatives.

Nanohardness is generally defined as a material's resistance to permanent or plastic deformation at the nano-micro level. In many materials, hardness is a measure of resistance to an indentation where a ball, diamond pyramid or cone is forced into the material being tested under an applied load (for our nanohardness a Berkovitch indenter is used at loads typically between 0.1mN and 300mN).

Summary of applications

The equipment is the latest version of the CSM-Nano Hardness Testing system, which offers enhanced capabilities in testing a wide range of manufactured or even soft biological and polymeric materials. It can provide modulus and hardness values under dynamic or creep loading protocols. Impression creep features of some materials have already been evaluated in particular with soft polymers and natural materials, and this facility is probably unique to the UK.

The facility provides a focus for materials development and fabrication, physical testing and failure analysis, materials composition and structure characterisation, the effects of radiation on materials and the application of materials in a wide range of industrial sectors.

General applications:

- Modulus and hardness measurements of a wide range of manufactured and natural materials;

- Depth and profiling of thin films and substrates;

- Topographical maps of consistency of properties over a wider area (typically 1cm2);

- Impression creep characteristics of various polymers and viscoplastic materials.

Materials of interest include:

- Metals,

- Ceramics,

- Composites,

- Semiconductors,

- Polymers,

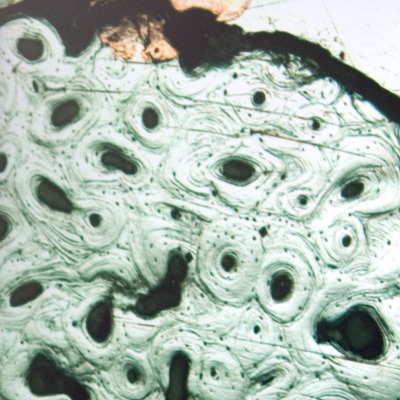

- Biological materials.

Using the facility

Uses of the facility include:

- Elasticity and hardness measurements of skin in relation to skin care products;

- Fuel cell membrane analysis and characterisation;

- Properties of conducting polymers;

- Insect cuticle material properties;

- Armour and impact materials under dynamic strain;

- Commercial testing of manufactured materials;

- Analysis of effects of radiation on materials and solar cells;

- Basic and applied research and development.