Micro-computed tomography (micro-CT) is used for a wide range of projects, from biomechanics to cultural heritage studies. Commercial 2D radiographic imaging and 3D micro- (and nano-) CT scanning is available. Data is available in a variety of formats as required. Imaging is available to researchers from Cranfield and other universities, as well as external clients, and prices are available on request.

Instrument specifications

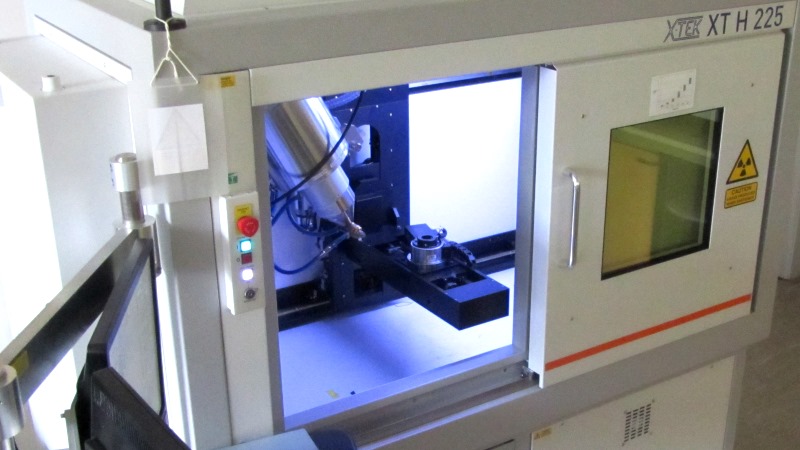

The system is a Nikon Metrology HMX ST 225 micro-CT with reflection and transmission targets and a maximum accelerating voltage of 225 kV. Resolution of 5-125 μm voxel size can be achieved depending on the size of the sample. The reflection target is used for most samples larger than 1 cm in diameter. Tungsten, Mo, Ag and Cu targets are available, depending on the sample material type. A transmission target is also available for smaller samples (nano-CT) but is only available for limited periods throughout the year and with prior agreement.

Sample specifications

Micro-CT analysis is suitable for a wide range of material and sample types, including bone and metal. Samples ranging in size from approximately 0.5cm to 20cm can be analysed (at the lower end of this scale, samples can be analysed using nano-CT). It may be possible to analyse larger samples for 2D radiographs, depending on the sample’s dimensions. The sample chamber can accommodate samples up to 10kg in weight, and a maximum height of around 60cm (although maximum vertical scan height is 12cm). The best images are achieved for cylindrical samples, where the X-rays have the same distance to penetrate from all angles (e.g. bones are best supported vertically rather than mounted horizontally). Very dense or flat samples may not produce good images.

How micro-CT works

The micro-CT system takes a series of X-ray images (radiographs) of an object as it rotates through 360°. These are then digitally reconstructed to produce a 3D volume, allowing visualisation of the internal and external structure of the sample. The technique is non-destructive. 2D radiographs can also be taken.

Summary of applications

As well as external consultancy clients, Cranfield Forensic Institute staff and students have access to our micro-CT facilities. Below are examples of recent projects to use micro-CT analysis.

Research projects:

- Microarchitecture changes in osteoporotic trabecular bone.

PhD projects:

- Nano-CT of archaeological dental calculus to visualise internal layering and trapped inclusions, and associated morphometric analysis;

- CT dual energy function to aid characterisation of unknown materials;

- Morphological and bone density studies of bone remodelling;

- Use of CT data to create meshes for use in finite element analysis (FEA) to assess damage in cancellous bone and the impact of vibration on spinal damage;

- Use of CT data for 3D printing: 3D printing of spinal models and comparison with real spines.

Recent MSc projects:

- Analysis of the absence of mandibular third molars in an Anglo-Saxon population;

- Ballistic impacts on bone;

- Investigations of blood spatter on textiles;

- Determining the internal structure of firearms and suppressors;

- Investigating beetle-damage of wood specimens;

- Measurements of bones within an Egyptian mummified hand.

Examples of consultancy use:

- Defect analysis, porosity, inclusions, failure investigations;

- Internal measurements.

Analysis is suitable for clients from a range of sectors including manufacturing, industry, archaeology and cultural heritage.

Using the facility

Uses include:

- Microarchitecture changes in osteoporotic trabecular bone;

- Nano-CT of archaeological dental calculus to visualise internal layering and trapped inclusions, and associated morphometric analysis;

- CT dual energy function to aid characterization of unknown materials;

- Morphological and bone density studies of bone remodelling;

- Use of CT data to create meshes for use in finite element analysis (FEA) to assess damage in cancellous bone and the impact of vibration on spinal damage;

- Use of CT data for 3D printing: 3D printing of spinal models and comparison with real spines;

- Analysis of the absence of mandibular third molars in an Anglo-Saxon population;

- Ballistic impacts on bone;

- Investigations of blood spatter on textiles;

- Determining the internal structure of firearms and suppressors;

- Investigating beetle-damage of wood specimens;

- Measurements of bones within an Egyptian mummified hand.

A list of recent publications from projects that have used the micro-CT:

- S. Brown, T. Higham, V. Slon, S. Pääbo, M. Meyer, K. Douka, F. Brock, D. Comeskey, N. Procopio, M. Shunkov, A. Derevianko, M. Buckley. 2016. Identification of a new hominin bone from Denisova Cave, Siberia using collagen fingerprinting and mitochondrial DNA analysis. Scientific Reports 6, article no. 23559 (doi: 10.1038/srep23559)

- Dicken, L., Knock, C., Beckett, S., de Castro, T.C., Nickson, T. & Carr, D.J. 2015. The use of micro computed tomography to ascertain the morphology of bloodstains on fabric. Forensic Science International 257: 369-375.

- Breeze, J., Carr, D.J., Mabbott, A., Beckett, S. & Clasper, J.C. 2015. Refrigeration and freezing of porcine tissue does not affect the retardation of fragment simulating projectiles. Forensic and Legal Medicine 32:77-83.

- Greenwood, C., Clement, J.G., Dicken, A.J., Evans, J.P.O., Lyburn, I.D., Martin, R.M., Rogers, K.D., Stone, N., Adams, G. and Zioupos, P., 2015. The micro-architecture of human cancellous bone from fracture neck of femur patients in relation to the structural integrity and fracture toughness of the tissue.Bone Reports, 3, pp.67-75.

- Greenwood, C., Clement, J., Dicken, A., Evans, J.P.O., Lyburn, I., Martin, R.M., Rogers, K., Stone, N. and Zioupos, P., 2016. Towards new material biomarkers for fracture risk. Bone,93, pp.55-63