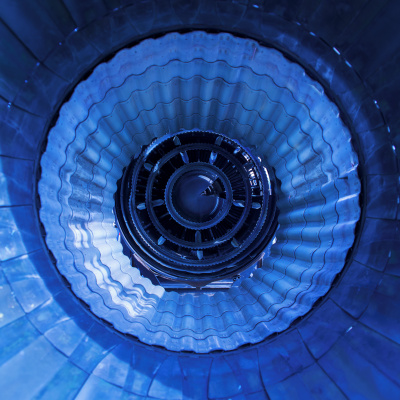

Our icing tunnel facilities are unique, comprising arguably the largest icing tunnel in the UK and the largest droplet tunnel for icing studies in the world. Opened by HRH Duke of Kent, the facilities have been the focus of a wide range of international research and development work.

Water droplets in clouds can cool well below freezing point and yet remain liquid. It is often only when they touch a solid object that they freeze. Aircraft, tall buildings, wind turbines and even crops can be greatly affected by the ice which forms on them due to windborne droplets. Ice growth rates can be over 1mm per minute, and the ice layer is often highly irregular and can give rise to major changes in the aerodynamic qualities of both natural and man-made structures. The weight of ice can also cause problems, especially on rapidly rotating parts such as helicopter blades and aero gas turbine engine fans. When ice fractures or warms up and falls away from whatever it has grown on, further problems can arise. Rotating parts can become dangerously out of balance and ice fragments falling or blowing around can cause mechanical damage and blockages.

About the facility

In our main icing tunnel, we are able to create realistic icing conditions at a component level, providing information on how well ice protection equipment is working and on the adhesion of ice to a given material. We collect information which helps to support the development of ice accretion modelling tools so that designers of aircraft, their engines and other exposed equipment can assess the likely impact of ice accretions on the performance of their devices.

In our droplet tunnel, we can examine how a single water droplet behaves as it strikes a surface at speed. This is our microscope on the icing process. It allows us to see the change in shape of droplets in an air flow as they move close to a solid surface and how they splash and spread when they strike the surface. We see how the water which does not freeze immediately flows and gathers as rivulets, attached droplets or forms a film of water. All this helps us to understand the icing process and find better ways to model it. It also helps us look into the potential of how highly engineered surfaces can be used to control ice growth.

Overview of icing tunnel (PDF)

The icing tunnel

The tunnel creates a stream of cooled air (down to -30°C) and mixes into it a fine mist of water droplets. A model can be placed in this stream to simulate the effects of passing through cloud at speed.

The tunnel is equipped with a multi-channel video monitoring and surveillance system and a National Instruments Field Point based flexible 16-bit signal monitoring and recording installation for temperatures, pressures and electrical signals.

Features of the main tunnel include:

- Main tunnel mass flow rate, 80 kg per second;

- Cooling capacity, 450 KW;

- Usual working section size, 761 mm x 761 mm;

- Mach 0.1 to 0.5;

- Total air temperature range from -30 to +30°C;

- Liquid water concentrations from 0.05 to 3 g/m3;

- Two independent sources of anti-icing air with a combined capacity150 KW;

- Droplet size 15 to 80 microns (with option to work with droplet sizes up to 300 microns).

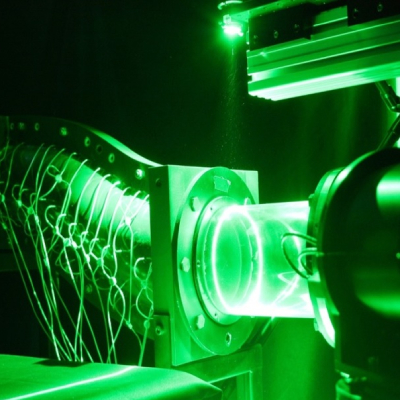

The cooled vertical droplet tunnel

This tunnel allows us to watch singular water droplets strike a surface at speeds. It is capable of generating and accelerating droplets in the diameter range from 10 to 1000 microns to speeds of up to 120 m/s. It may be operated with air temperatures from +30 to -20°C.

The tunnel is approximately 8 meters long and features a very gentle contraction to promote good matching of droplet and air speed and temperature and to minimise droplet distortion and break-up. The droplets are produced by a mono-dispersed generator of designed specifically for the facility located in the mouth of the tunnel.

Air is driven through the tunnel using the fan and cooling equipment associated with the adjacent Cranfield icing tunnel.

The base of the tunnel includes a bifurcated duct with two butterfly valves to create a range of flow conditions in the working section.

Summary of applications

The facilities at Cranfield University are used primarily as follows:

- We want to understand the physical processes and the nature of the properties of ice produced;

- We want to help predicate how ice will grow and the impact of manufactured and used products;

- To prove that any ice protective measures are effective and to prove predictions.

Our industrial clients – Jaguar, Airbus and Rolls Royce, NASA and SNECMA to name a few – have used the icing tunnel for investigation of the following:

- Testing new ice protection equipment;

- Validating design tools for simulating ice growth and ice response to ice protection measures;

- Examining the potential role of ice phobic surface coatings;

- Basic studies of ice growth and behaviour to support the development of new ice prediction methods;

- Ice growth and behaviour inside pipes;

- Basic studies on fine scale fluid mechanics and phase change;

- Demonstration of novel ice protection concepts.

The following sectors have the requirement for the use of an icing tunnel:

- Aerospace,

- Automotive,

- Wind energy.