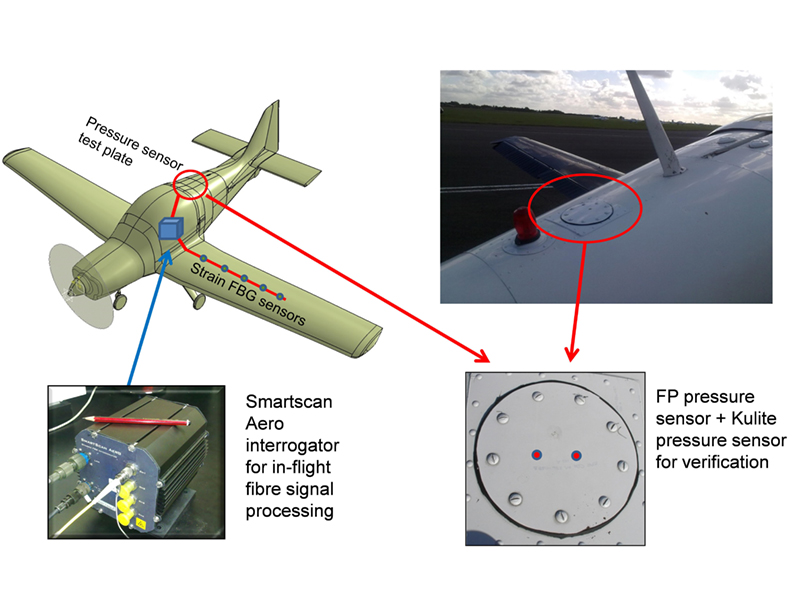

We have been developing advanced fibre optic sensors for aircraft flight test, initially in a major collaboration of European aerospace research institutions and industrial partners. We used our own Scottish Aviation Bulldog light aircraft based at Cranfield Airport during this research.

Key facts

-

The Advanced In-Flight Measurement Techniques (AIM and AIM 2) research programmes ran for eight years from 2006 and developed advanced optical measurement systems for in-flight measurement. AIM 2 was a four-year project totalling €3.75 million which saw us partner with a number of European aerospace research institutions and industrial partners, led by DLR in Germany.

-

We developed fibre optic sensors which have been successfully tested in flight at up to +6g. Our work continues in a number of UK-funded research programmes with industrial partners including Airbus and Rolls-Royce.

-

Fibre optic sensors can be developed with thicknesses less than a human hair (150 microns), used to measure pressure to less than 1/100000th of an atmosphere, and can be permanently embedded inside modern aircraft structures to monitor the structure’s health over the life of the aircraft.

- Funded by European Commission’s Sixth and Seventh Framework Programmes (FP6 and FP7), for the AIM research programmes.

Impact of our research

Numerous flight tests of systems and equipment, including use of our Scottish Aviation Bulldog light aircraft, were conducted by the AIM partners. The fibre optic sensors measuring pressure and strain were successfully tested on the Scottish Aviation Bulldog light aircraft in steady and dynamic manoeuvres (over a g-load range of -1g to +6g). Using 150 micron diameter fibres, the resolution of the sensors has been shown to be equivalent to, or better than, conventionally available sensors but with a significantly smaller footprint and no electromagnetic limitations.

The fibre optic pressure and strain sensors developed in AIM 2 are being adapted for use in major wind tunnel facilities in the UK, including those of Airbus and the Aircraft Research Association (ARA). The £17 million WINg Design methodology (WINDY) UK-funded research project aims to use the fibre optic sensors as part of a major research programme, involving the likes of Airbus and Rolls-Royce, to develop advanced manufacturing methods for aircraft wing design and test facilities.

Why the research was commissioned

The flight test and certification of aircraft is a complex and costly process. New advanced instrumentation, which can be used for the certification of the aircraft or used as integrated part of the aircraft systems including fibre optic systems, offers many benefits. This will ultimately lead to either a faster and more cost-effective certification process or in-service benefits for future aircraft.

The two European research programmes, AIM and AIM 2, focused on the development of novel optical methods for flight tests. By the end of the programme, more than 10 flight test programmes were completed with advanced sensors on various European flight test aircraft including our own Scottish Aviation Bulldog. Our research continues with a number of UK-funded research programmes with industrial partners including Airbus and Rolls-Royce.

Why Cranfield?

We were an ideal partner in the European AIM research programmes due to our international track record in fibre optic sensor research. We also have a unique heritage in flight test and access to flight test platforms, such as the Scottish Aviation Bulldog and Jetstream aircraft which are part of our National Flying Laboratory Centre (NFLC).

Facilities used

-

Engineering Photonics Laboratory.

-

National Wind Tunnel facility.

-

High Performance Computing facility.

-

National Flying Laboratory Centre (NFLC) Scottish Aviation Bulldog light aircraft based at Cranfield Airport.