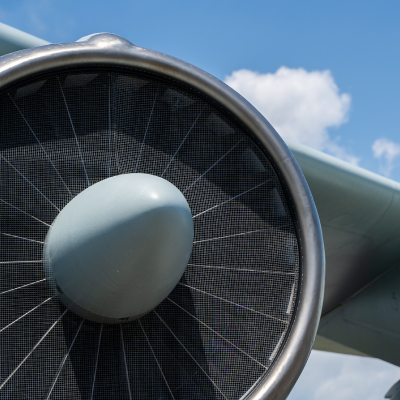

Aircraft manufacturers today face the challenge of developing lighter, more fuel-efficient and environmentally-friendly aircraft; requiring the development of novel aero-structures that make effective use of advanced materials.

- Structural Design, Analysis and Optimisation – examining how structures are currently performing in prescribed conditions and making recommendations for improvement.

- Crash and Impact Response – analysis of structural impact resistance for example when ditching, during bird strike, hard landing or entering atmosphere.

- Fatigue and Fracture – practical methods for meeting the durability and damage tolerance requirements of modern-day aero-structures.

- Fluid-Structure Interaction – providing an elegant solution to problems combining deformable structures and fluids.

- Fault Tolerance Design – including the use of composites, optimising structures for loads and fuel consumption.

- Fault Detection and Health Monitoring – for example the effect of noise and vibration on turbine blades or the use of sensors to optimise and extend service life.

- Advanced and Composite Materials – for example carbon fibre or bulk metallic glasses.

Our work encompasses a variety of flying structures including aircraft, helicopters, satellites, UAVS and missiles. As a result, our client list is extensive and includes Airbus, Airbus Military, AgustaWestland, BAE Systems, Boeing, Dassault Aviation, EADS Astrium, Lockheed Martin, Marshall Aerospace, MBDA, Rolls Royce, Sprint Aviation, Surrey Satellite Technology Ltd and Vega.

About our research

Our greatest strength is the ability to combine the academic rigour and long-term perspective of a university with the commercial and business focus of industry.

Our excellence in strategic and applied research has enabled us to make significant contributions to the world around us for over 60 years. We address real life challenges and focus on research that is of strategic and practical importance.

We provide a supportive research community for students and our academic work is regularly published in journal article, book or thesis form.

Working with us

Businesses can work with us on research of all scales from sponsorship of MSc student projects to research and development programmes extending over several years.

We have a wealth of facilities and resources at our disposal to provide tailored solutions to a variety of structural problems. We can provide structure design capabilities from preliminary to detailed. An exciting part of our work involves exploring new structural concepts such as the blended wing body.

Commercial software packages, whilst readily available, cannot always provide managers with adequate information for assisting airframe and component management decisions for example inspection times to maintain airworthiness standards. We have extensive experience with developing and extending simulation tools and experimental techniques for testing and optimisation of structures and materials under static, dynamic and impact loading, including:

• Linear and Non-Linear Finite Element Methods

• Meshless Methods such as Smoothed Particle Hydrodynamics (SPH)

• Constitutive models for metallic and non-metallic materials.