In all honesty, I like the way that Cranfield is very research orientated. I like the fact that you get to work on a large range of different projects. At other universities you might be employed on just one project, whereas here you get to work on a number of different projects. This means I'm forming great networks of skilled people, and we get to cross-pollinate ideas and find good synergies, which gets more ideas going.

What are your areas of interest in the Energy sector?My background is material science and engineering, so I am really interested in looking at metals, and seeing how they start to break down. You can get some really lovely microstructures. Most people look at a lump of metal and say, ‘Oh, it’s a bit grey.’ Then it gets corroded and they add, ‘Oh it’s dirty and grey.’

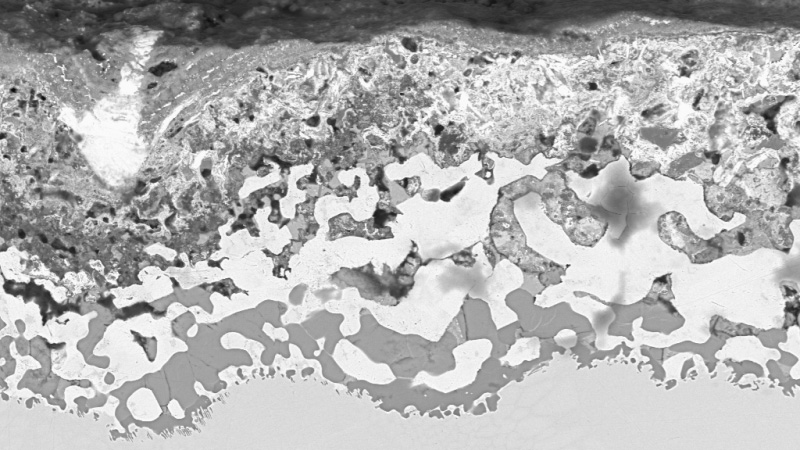

In fact, if you start to look at it in detail you can see all of these really beautiful patterns. Seen through a normal microscope, you can have many different, vivid colours in the metals from some of the precipitates, oxides (rust) or coatings. If you look in an Scanning Electron Microscope (SEM) the details are only shown up in white and black, but they’ll have all of these different shapes: some can be quite fractal; some can be nice round; others are can have systematic square patterns. It can also look a bit like crazy paving!

Anyway to return to my background: material science and energy! Today there is a lot of interest in trying to get new fuels into use. These might be fuels that can help to limit CO2 emissions; this could involve using biofuels for instance. However, different fuels mean you’ve got different chemical species in the burnt gas and that can cause corrosion issues.

At the same time, there is also interest in trying to cycle existing power plants against renewables. ‘Cycling plant’ means that, for example, if it’s windy and there’s a lot of power coming from wind turbines, you need less energy from conventional plant and shut some down. Then, when it stops being windy, you switch back to your conventional plant. We need to do this because, currently, we don’t have much energy storage capacity, so on that windy day you require much less conventional power, but once the wind stops blowing you need to return to conventional sources. You can’t store up any excess.

This cycling causes strain on power plants. You might have noticed something similar with old tungsten filament light bulbs; if you turn on and off repeatedly they break quickly. Similarly, engines and turbines will have problems if you flick them on and off too often. Put this together with the new fuels and there’s a wide range of materials-related problems to look at!

What is your research background?I am probably a fairly typical academic in some ways in that I went to university and continued into academia. I was going to study physics, but within about two weeks at university I came across this wonderful subject that dealt with all these metals and materials and real-world situations. To cut a long story short, I fell madly in love with it and I’ve been off, researching materials ever since.

I studied natural sciences as an undergraduate over at Cambridge. I got to go to America for a year at that time and studied at Massachusetts Institute of Technology (MIT). When I came back, I did my Masters. After that I went into a PhD in semi-conductors; in particular doing a microscopy of semiconductor materials which are quite different from metals, but the actual microscopy techniques you use are universal no matter what material you want to look at. With some modifications you could be studying cells, dried plant extract, metals, semiconductors or superconductors. Following my PhD, I went to Japan to teach for a year, which was very nice; I recommend it. It taught me a lot about how to explain things clearly to my students.

After I came back, I worked briefly at the University of Bath, still on semiconductors, after which I saw an advert to come and do microscopy work here. So I'm back where it all started, working on metals.

What current research projects are you involved in?I’m involved in a range of different projects. Some can be linked to governmental funding, such as Flex-E Plant, which is supported by the EPSRC (Engineering and Physical Sciences Research Council). Flex-E-Plant looks at flexible plant operations, asking questions such as: What happens when you’re cycling again renewable power? What’s the best way of integrating different power generators? What types of problems might arise? What can be done to mitigate the problems? Then there are the industrial projects. These can range from quite long-term projects to much more shorter, consultancy-type collaborations.

What are your plans for future research?At the moment I’m interested in empirical modelling of corrosion development, which will be useful to a large number of projects that I’m involved in. I’m interested in seeing how we can expand current models and, as part of that, you have to think, ‘What happens if I have this particular environment and temperature, and that material with those constituents in it? How long do I expect the material to last?’

This matters because the one thing you don’t want is for something to go ‘bang’ in a machine and to suddenly have an unplanned outage. At least if you know when you expect significant damage you can make maintenance plans. So yes, this is where I like to work.

What courses do you teach?At the moment I’m a deputy course tutor for Offshore and Ocean Technology, which is a group of five MSc. I teach quite heavily on modules to do with materials and corrosion in the offshore environment. Offshore corrosion is the type of corrosion people normally think about when you say ‘corrosion’. It takes place at fairly low temperatures, and is the processes that occur when you put things into seawater or your car starts to corrode. (Most of my day-to-day research is at much higher temperatures; usually several hundred degrees Celsius). It’s nice to be involved in both low temperature/wet and high temperature corrosion because you can see the parallels as well as the differences. It’s a bit like when you go abroad and see ‘gelato’; it’s still ice-cream, but it’s different.

What elements of teaching do you most enjoy?I like the group and individual project work most. I like the chance to work with the students, see how they develop their ideas and tackle problems. They’ve got quite a length of time to work on their projects and they can cover the full a huge range of interesting issues.

How have you found Cranfield so far?I find the people here are positive and energised. I like working with the students because they often look at things from a slightly different angle so when trying to explain something, it can often make you re-assess your own assumptions. Plus they get excited about the bits of research that you think are less interesting because they see something slightly different in it than you do. It can keep you from getting stuck in a rut in how you approach things.

In terms of facilities we’ve got some really great pilot-scale facilities for hot corrosion. They're often the best in the UK for the specific things they do, and in some areas are world-leading. We do have some really great high temperature corrosion facilities here.