Contact Dr Geoffrey Neale

- Tel: +44 (0) 1234 754418

- Email: G.D.Neale@cranfield.ac.uk

- ORCID

- Google Scholar

- ResearchGate

Areas of expertise

- Aerospace Manufacturing

- Composites

- Computing, Simulation & Modelling

- Manufacturing of Functional Materials

- Aerospace Materials

Background

Dr Geoffrey Neale graduated from the University of Bristol with an MEng in Aerospace Engineering then went on to pursue a PhD in Advanced Composite Materials at the Engineering Composites Research Centre at Ulster University, where he worked as part of the EU Horizon 2020 Marie Sklodowska-Curie ITN ICONIC. The ICONIC project focused on improving the crashworthiness of composite materials and Geoff's PhD research developed crashworthy, functionally graded 3D woven composites for use in aerospace and automotive structures. He helped to expand the understanding of the behaviour of these materials and refine material design for manufacturability. Before joining Cranfield University, Geoff held a postdoctoral position at Ulster University working jointly between the School of Engineering and the School of Biomedical Sciences. During his time as a postdoctoral research fellow at Cranfield, Geoff worked on the manufacture and characterisation of functional through-thickness reinforced composite materials as part of the EU funded SEER project (A 'Smart' Self-monitoring composite tool for aerospace composite manufacturing using Silicon photonic multi-sEnsors Embedded using through-thickness Reinforcement techniques).

Current activities

Geoff is a Royal Academy of Engineering (RAEng) Research Fellow and Lecturer in the Composites and Advanced Materials Centre. His RAEng funded fellowship is titled multifunctional z-direction hybridisation of composites and his wider area of focus is on multifunctional composite structures with a view to achieving multifunctionality in composites via material hybridisation. He has a particular interest in hybridisation via the application of through-thickness reinforcement methodologies. He is interested both structural and non-structural analysis of composites and in how novel fabrication methods can be used to achieve this, expanding the use of composites beyond its traditional industries.

Clients

Royal Academy of Engineering

European Commission

British Academy

National Composites Centre

Publications

Articles In Journals

- Neale G. (2025). International collaboration. FST Journal, 23(10)

- Kyriazi E, Petsinis G, Zervos C, Poulopoulos I, Syriopoulos G, .... (2025). ML-based surrogate cure simulation for predicting process time and temperature overshoot in resin transfer moulding. Journal of Reinforced Plastics and Composites, ahead-of-print(ahead-of-print)

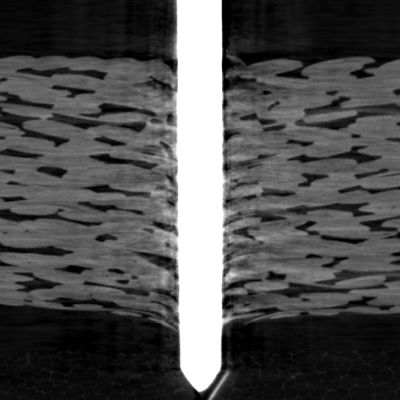

- Neale G, Saaran V, Dahale M & Skordos AA. (2024). An evaluation of large diameter through-thickness metallic pins in composites. Composite Structures, 337

- Neale G & Skordos AA. (2022). Insertion of large diameter through-thickness metallic pins in composites. Materials & Design, 216(April)

- Ralph C, Dahale M, Neale G, Ramaswamy K, McCarthy M, .... (2021). Influence of binder float length on the out-of-plane and axial impact performance of 3D woven composites. Composites Part A: Applied Science and Manufacturing, 147(August)

- Neale G, Gaihre S, O’Gorman P, Price RK, Balzategi AG, .... (2021). Review of recent innovations in portable child growth measurement devices for use in low- and middle-income countries. Journal of Medical Engineering & Technology, 45(8)

- Yoo S, Dahale M, Neale G, Toso N, Catalanotti G, .... (2021). Experimental Investigations of 3D Woven Layer to-Layer Carbon/Epoxy Composites at Different Strain Rates. EPJ Web of Conferences, 250

- Neale G, Dahale M, Yoo S, Toso N, McGarrigle C, .... (2020). Improved crush energy absorption in 3D woven composites by pick density modification. Composites Part B: Engineering, 192

- Dahale M, Neale G, Lupicini R, Cascone L, McGarrigle C, .... (2019). Effect of weave parameters on the mechanical properties of 3D woven glass composites. Composite Structures, 223

Conference Papers

- Kyriazi E, Petsinis G, Zervos H, Poulopoulos G, Syriopoulos G, .... (2024). Photonic sensor-based machine learning for precise forecasting of cure time and temperature overshoot in resin transfer moulding

- Kyriazi E, Petsinis G, Poulopoulos I, Syriopoulos G, Prousalidi T, .... (2024). Photonic sensors-assisted ML pipeline for precise control of curing process in advanced thermosetting composite manufacturing

- Neale G, De La Cruz Martinez ML & Skordos A. (2024). The case for macroscale through-thickness reinforcement for hybridised multifunctional composites

- Neale G, Fu Y & Skordos A. (2023). Z-direction heat transfer in composites hybridised with large diameter metallic pins

- Neale G, Saaran V, Dahale M & Skordos S. (2022). Characterisation of large diameter through-thickness metallic pins in composites

- Archer E, McIlhagger A, Harkin-Jones E, Neale G, Ralph C, .... (2020). 3D weaving and consolidation of carbon fibre T-piece stringers

- Neale G, Dahale M, Yoo S, Toso N, Kelly J, .... (2019). Energy absorption mechanisms in layer-to-layer 3D woven composites

- Dahale M, Neale G, McGarrigle C, Kelly J, Archer E, .... (2019). Comparative studies of structure-property relationship between glass/epoxy and carbon/epoxy 3d woven composites

- Neale G, Dahale M, Yoo S, Toso N, McGarrigle C, .... (2019). Improved Energy Absorption in 3D Woven Composites by Weave Parameter Manipulation

- Dahale M, Neale G, McGarrigle C, Kelly J, Archer E, .... (2019). Influence of textile architecture on the mechanical properties of 3d woven carbon composites

- Dahale M, Neale G, Mcllhagger A, Archer E & Harkin Jones E. (2018). Effect of pick density on tensile, compressive and shear properties of 3D woven glass composites

- Neale G. (2018). 3D woven composites for energy absorbing applications

- Neale G. (2018). Effective triggering of omega-shaped 3D woven composite components for progressive crush initiation

Books

- Dahale M, Archer E, McIlhagger A, Ralph C, Neale G, .... (2023). Three-dimensional woven composites In Harper L & Clifford M (eds), Design and Manufacture of Structural Composites. Woodhead Publishing.

- Dahale M, Archer E, McIlhagger A, Ralph C, Neale G, .... (2023). 8 Three-dimensional woven composites In Design and Manufacture of Structural Composites. Elsevier.

- Dahale M, Archer E, McIlhagger A, Ralph C, Neale G, .... (2023). Three-dimensional woven composites In Design and Manufacture of Structural Composites. Elsevier.