Contact Dr Ali Nabavi

- Tel: +44 (0) 1234 754225

- Email: s.nabavi@cranfield.ac.uk

- ORCID

- Google Scholar

Areas of expertise

- Carbon Capture and Storage

- Computational Fluid Dynamics

- Conventional & Advanced Fuels

- Energy and the Environment

- Low Carbon Technology

Background

Dr Nabavi is Readrer in Energy Systems and Head of Centre for Energy Decarbonisaion and Recovery (CEDAR). He is the Director of Advanced Chemical Engineering Course. He obtained his MSc in Thermal Power and Fluid Engineering with Distinction from The University of Manchester in 2012, where he worked on the development of numerical models for turbulent impinging and swirling jets. He received his PhD in Energy from Cranfield University in 2016, where he developed emulsion-based selective materials for carbon capture, and utilised CFD modelling to optimise their production processes. He then continued working as a Research Fellow on low-carbon energy systems until his appointment as Lecturer in 2018, where he developed a kW-scale solid oxide fuel cell system integrated with a carbonate looping process for simultaneous power generation and direct air capture.

Dr Nabavi has successfully led the delivery of commercial and research projects in clean and sustainable energy systems, including sorbent developments for separation and purification, novel concept prototyping, technology assessment, and computational modelling.

Research opportunities

Dr Nabavi is currently accepting self-funded PhD and research applications in the following research areas:

1. Development, characterisation, and bench-to-pilot testing of CO2 sorbents for decarbonisation of flue gases, biogas upgrading to biomethane, hydrogen production and purification, and direct air capture.

Available facilities:

- Well-equipped material synthesis lab

- Material characterisation facilities

- Gas capture and separation facilities: a number of bench-scale and pilot-scale fixed- and fluidised bed reactors for low- and high temperature (up to 1000 C) gas capture.

2. System integration of solid oxide fuel cells and electrolysers in transport and industrial processes for fuel flexibility.

Available facilities:

- kW-scale SOFC/SOEC testing rig

- A series of SOFC/SOEC stacks (0.7-5 kW)

- Material characterisation facilities

3. Simulation and computationally modelling of

- Gas sorption, separation, and conversion

- Microscale-to-macroscale hydrodynamics, heat transfer, chemical, and electrochemical reaction

- Multiphase flow for emulsion formation (microfluidics, membrane, and stirred-tank reactor)

- Process intensification (gas-solid and gas-liquid systems)

- Hydrogen carrier combustion

Available facilities:

- Cranfield's High-Performance Computing (HPC) facilities

- A number of commercial CFD software, such as ANSYS Fluent.

Current activities

Dr Nabavi's research combines experimental and computational approaches to develop innovative solutions to advance low-carbon energy systems. A major focus of his research is to apply fundamentals of thermofluid, multiphase flow, and reactive transport processes to:

- Carbon Capture Utilisation and Storage (CCUS) and Carbon Dioxide Removal (CDR): Synthesis, characterisation, and bench-to-pilot scale testing of carbon capture materials for industrial carbon dioxide removal, biogas upgrading to biomethane, hydrogen production and purification, direct air capture, and sustainable fuel production.

- Reversible solid oxide fuel cell and electrolysers: Fuel flexibility in transport, industrial and energy storage applications.

- Process intensification for energy efficiency: Integration of fuel cells in carbon-intensive processes; Active intensification of gas-solid processes, and heat transfer enhancement.

- Microfluidic and lab-on-chip: Particle formulation and production, and sorption analysis.

Teaching Activities

Dr Nabavi has a substantial track record of teaching, supervision, and training of students, researchers, and industry delegates, and provides skill training and bespoke courses on the following topics:

Sorption, Separation and Purification towards Net-Zero target

- Carbon capture storage (CCUS) for industrial carbon dioxide removal, biogas upgrading to biomethane, hydrogen purification, direct air capture

- Production and conversion of sustainable fuels (hydrogen, biogas, biomethane, methanol, ammonia, and SAF)

- Low- and high-temperature CO2 capture materials

- Adsorption and absorption principles

- Design of cyclic sorption technologies

- Negative-emission technologies (DAC, BECSS, and weathering)

Thermal Systems Operation and Design

- Conduction and convection heat transfer principles and CFD modelling of thermal systems

- Heat exchanger design and pinch analysis

- Refrigeration and air conditioning design

- Waste heat recovery and thermal storage

Clients

Department for Business, Energy and Industrial Strategy (BEIS)

Innovate UK

Engineering and Physical Sciences Research Council

Meggitt

Origen Power

Cadent

ZeroAvia

Epicam

Cambridge Engineering Analysis & Design (CEAD)

Oman LNG

Lapwing Energy

Thermal Energy International (UK)

Publications

Articles In Journals

- Ogunedo BMO, Rees G & Nabavi SA. (2026). Probing the influence of water on silica surface modification during amine grafting for enhancing CO2 adsorption. Chemical Engineering Journal, 527

- Dhodduraj K, Narisetty V, Nabavi SA, Parra-Saldívar R, Coulon F, .... (2026). Beets beyond sugar: potential and limitations of sugar beet pulp as a feedstock for biorefineries. Industrial Crops and Products, 240

- Wang S, Shen Z, Osatiashtiani A, Nabavi SA & Clough PT. (2025). Experimental and DFT study of (sorption-enhanced) steam methane reforming over bimetallic Ni-Cu catalysts. Fuel, 381, Part D

- Farooqi AS, Allam AN, Shahid MZ, Aqil A, Fajri K, .... (2025). Advancements in sorption-enhanced steam reforming for clean hydrogen production: a comprehensive review. Carbon Capture Science & Technology, 14

- Kasar I, Fotouhi A & Nabavi SA. (2025). Performance test of a hydrogen-powered solid oxide fuel cell system and its simulation for vehicle propulsion application. Journal of Cleaner Production, 486

- Gordon JA, Balta-Ozkan N, Haq AUL & Nabavi SA. (2025). Fuelling hydrogen futures? A trust-based model of social acceptance. Sustainable Energy & Fuels, 2025(9)

- Ogunedo BMO, Wadi B, Manovic V & Nabavi SA. (2025). Unveiling host-guest interactions and stability of amine-functionalized silica sorbents for carbon capture. Materials Today Sustainability, 30

- Golmakani A, Khallaghi N, Amiri A, Manovic V & Nabavi SA. (2025). Techno-economic assessment of pressure swing adsorption tail gas decarbonisation for blue hydrogen production. Gas Science and Engineering, 142

- Awani K, Khallaghi N, Kumar V & Nabavi SA. (2025). Techno-economic assessment of an integrated GTL facility for urea production. Journal of CO2 Utilization, 99

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2024). Gauging public perceptions of blue and green hydrogen futures: is the twin-track approach compatible with hydrogen acceptance?. International Journal of Hydrogen Energy, 49, Part D

- Shen Z, Nabavi SA & Clough PT. (2024). Design and performance testing of a monolithic nickel-based SiC catalyst for steam methane reforming. Applied Catalysis A: General, 670

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2024). Towards a unified theory of domestic hydrogen acceptance: an integrative, comparative review. International Journal of Hydrogen Energy, 56

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2024). Exploring the contours of consumer heterogeneity: towards a typology of domestic hydrogen acceptance. Energy Research & Social Science, 108

- Gordon JA, Balta-Ozkan N, Haq A & Nabavi SA. (2024). Coupling green hydrogen production to community benefits: a pathway to social acceptance?. Energy Research & Social Science, 110

- Wang S, Shen Z, Osatiashtiani A, Nabavi SA & Clough PT. (2024). Ni-based bimetallic catalysts for hydrogen production via (sorption-enhanced) steam methane reforming. Chemical Engineering Journal, 486

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2024). Hopes and fears for a sustainable energy future: enter the hydrogen acceptance matrix. International Journal of Hydrogen Energy, 60

- Gordon JA, Balta-Ozkan N, Haq A & Nabavi SA. (2024). Necessary and sufficient conditions for deploying hydrogen homes: a consumer-oriented perspective. International Journal of Hydrogen Energy, 69

- Gordon JA, Balta-Ozkan N, Haq AU & Nabavi SA. (2024). Heterogeneous preferences for living in a hydrogen home: an advanced multigroup analysis. Sustainable Energy & Fuels, 8(12)

- Shen Z, Nabavi SA & Clough PT. (2024). An investigation of monolithic nickel-based catalyst for clean hydrogen production with CCS technology: the effect of structure. Fuel, 371, Part B

- Bazooyar B, Nabavi SA, Clough P, Anthony EJ & Manovic V. (2024). Towards decarbonisation of sugar refineries by calcium looping: Process integration, energy optimisation and technoeconomic assessment. Energy Conversion and Management, 314

- Shen Z, Nabavi SA & Clough PT. (2024). Intrinsic kinetics of steam methane reforming over a monolithic nickel catalyst in a fixed bed reactor system. Chemical Engineering Science, 299

- Jomekian A, Alhasnawi BN, Bazooyar B, Nabavi SA & Varasteh H. (2024). The effect of hydrogen fuel on the performance and emissions of 3 kWe natural gas fuelled microturbine. Fuel, 376

- Kumar R, Liu H, Nabavi SA, Anyebe MS, Mahesh S, .... (2024). Impact of Indium Doping in Lead-Free (CH3NH3)3Bi2–x In x I9 Perovskite Photovoltaics for Indoor and Outdoor Light Harvesting. ACS Applied Electronic Materials, 6(11)

- Gordon JA, Balta-Ozkan N, Haq AU & Nabavi SA. (2024). Modelling the innovation-decision process for hydrogen homes: an integrated model of consumer acceptance and adoption intention. International Journal of Hydrogen Energy, 94

- Awani K, Hanak D, Kumar V & Nabavi SA. (2024). Techno-economic assessment of decarbonization pathways for a gas to liquid facility: a review. Journal of CO2 Utilization, 90(Environ. Sci. Technol. 41 17 2007)

- Khallaghi N, Ghiami S, Jeswani H, Nabavi SA & Anthony EJ. (2024). Blue hydrogen production through partial oxidation: a techno‐economic and life cycle assessment. International Journal of Energy Research, 2024(1)

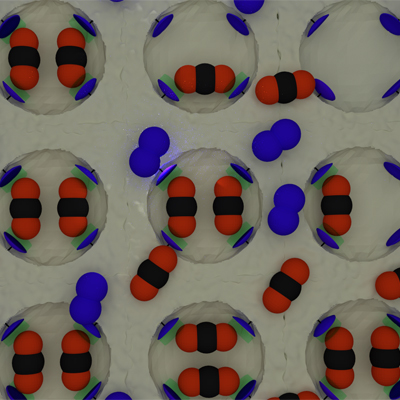

- Wadi B, Golmakani A, Borhani TN, Manovic V & Nabavi SA. (2023). Molecular simulation techniques as applied to silica and carbon-based adsorbents for carbon capture. Energies, 16(13)

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2023). Socio-technical barriers to domestic hydrogen futures: repurposing pipelines, policies, and public perceptions. Applied Energy, 336(April)

- Wadi B, Li C, Manovic V, Moghadam P & Nabavi SA. (2023). Contributions of CH4-amine interactions by primary, secondary, and tertiary amines on CO2/CH4 separation efficiency. Chemical Engineering Journal, 463(May)

- Bazooyar B, Zhu M, Manovic V & Nabavi SA. (2023). Direct numerical simulation of packed and monolith syngas catalytic combustors for micro electrical mechanical systems. Energy Conversion and Management: X, 20(October)

- Asibor JO, Clough PT, Nabavi SA & Manovic V. (2023). A machine learning approach for resource mapping analysis of greenhouse gas removal technologies. Energy and Climate Change, 4(December)

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2023). Divergent consumer preferences and visions for cooking and heating technologies in the United Kingdom: make our homes clean, safe, warm and smart!. Energy Research and Social Science, 104(October)

- Golmakani A, Wadi B, Manovic V & Nabavi SA. (2023). Comparative evaluation of PSA, PVSA, and twin PSA processes for biogas upgrading: the purity, recovery, and energy consumption dilemma. Energies, 16(19)

- Asibor JO, Clough PT, Nabavi SA & Manovic V. (2023). A machine learning approach for country-level deployment of greenhouse gas removal technologies. International Journal of Greenhouse Gas Control, 130(December)

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2023). Price promises, trust deficits and energy justice: public perceptions of hydrogen homes. Renewable and Sustainable Energy Reviews, 188(December)

- Wang S & Nabavi SA. (2023). A review on bi/polymetallic catalysts for steam methane reforming. International Journal of Hydrogen Energy, 48(42)

- Agrawal D, Awani K, Nabavi SA, Balan V, Jin M, .... (2023). Carbon emissions and decarbonisation: the role and relevance of fermentation industry in chemical sector. Chemical Engineering Journal, 475(November)

- Nag Srinath A, Pena López Á, Fashandi SAM, Lechat S, di Legge G, .... (2022). Thermal management system architecture for hydrogen-powered propulsion technologies: practices, thematic clusters, system architectures, future challenges, and opportunities. Energies, 15(1)

- Golmakani A, Nabavi SA, Wadi B & Manovic V. (2022). Advances, challenges, and perspectives of biogas cleaning, upgrading, and utilisation. Fuel, 317(June)

- Al Rizeiqi NM, Al Rizeiqi N & Nabavi SA. (2022). Potential of underground hydrogen storage in Oman. Journal of Advanced Research in Applied Sciences and Engineering Technology, 27(1)

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2022). Beyond the triangle of renewable energy acceptance: The five dimensions of domestic hydrogen acceptance. Applied Energy, 324(October)

- Asibor JO, Clough PT, Nabavi SA & Manovic V. (2022). A country-level assessment of the deployment potential of greenhouse gas removal technologies. Journal of Environmental Management, 323(December)

- Bazooyar B, Coomson G, Manovic V & Nabavi SA. (2022). Comparative analysis of ammonia combustion for domestic applications. Journal of the Energy Institute, 106(February)

- Gordon JA, Balta-Ozkan N & Nabavi SA. (2022). Homes of the future: unpacking public perceptions to power the domestic hydrogen transition. Renewable and Sustainable Energy Reviews, 164(August)

- Wadi B, Golmakani A, Manovic V & Nabavi SA. (2021). Effect of combined primary and secondary amine loadings on the adsorption mechanism of CO2 and CH4 in biogas. Chemical Engineering Journal, 420(September)

- Asibor JO, Clough PT, Nabavi SA & Manovic V. (2021). Assessment of optimal conditions for the performance of greenhouse gas removal methods. Journal of Environmental Management, 294(September)

- Wadi B, Mahomed A, Bai Y, Osatiashtiani A, Manovic V, .... (2021). Formulation, adsorption performance, and mechanical integrity of triamine grafted binder-based mesoporous silica pellets for CO2 capture. Powder Technology, 393(November)

- Wadi B, Golmakani A, Manovic V & Nabavi SA. (2021). Evaluation of moderately grafted primary, diamine, and triamine sorbents for CO2 adsorption from ambient air: balancing kinetics and capacity under humid conditions. Industrial & Engineering Chemistry Research, 60(36)

- N. Borhani T, Nabavi SA, Hanak DP & Manovic V. (2021). Thermodynamic models applied to CO2absorption modelling. Reviews in Chemical Engineering, 37(8)

- Gao Y, Golmakani A, Nabavi SA, Jiang J & Manovic V. (2021). Simulative optimization of catalyst configuration for biogas dry reforming. International Journal of Hydrogen Energy, 46(24)

- Heenan TMM, Nabavi SA, Erans M, Robinson JB, Kok MDR, .... (2020). The role of bi-polar plate design and the start-up protocol in the spatiotemporal dynamics during solid oxide fuel cell anode reduction. Energies, 13(14)

- Hossain MA, Nabavi SA, Ranganathan P, Könözsy L & Manovic V. (2020). 3D CFD modelling of liquid dispersion in structured packed bed column for CO2 capture. Chemical Engineering Science, 225

- Golmakani A, Nabavi SA & Manovic V. (2020). Production of negative-emission biomethane by twin double-bed pressure swing adsorption with tail gas sequestration. Chemical Engineering Journal, 408

- Matuszny K, Borhani TN, Nabavi SA & Hanak DP. (2020). Integration of solid-oxide fuel cells and absorption refrigeration for efficient combined cooling, heat and power production. Clean Energy, 4(4)

- Fayemiwo KA, Chiarasumran N, Nabavi SA, Manović V, Benyahia B, .... (2020). CO2 capture performance and environmental impact of copolymers of ethylene glycol dimethacrylate with acrylamide, methacrylamide and triallylamine. Journal of Environmental Chemical Engineering, 8(2)

- Golmakani A, Nabavi SA & Manovic V. (2019). Effect of impurities on ultra-pure hydrogen production by pressure vacuum swing adsorption. Journal of Industrial and Engineering Chemistry, 82

- Nabavi SA, Erans M & Manovic V. (2019). Demonstration of a kW-scale solid oxide fuel cell-calciner for power generation and production of calcined materials. Applied Energy, 255

- Erans M, Nabavi SA & Manovic V. (2019). Carbonation of lime-based materials under ambient conditions for direct air capture. Journal of Cleaner Production, 242

- Erans M, Nabavi SA & Manovic V. (2019). Pilot-scale calcination of limestone in steam-rich gas for direct air capture. Energy Conversion and Management: X, 1

- Fayemiwo K, Chiarasumran N, Nabavi SA, Loponov KN, Manovic V, .... (2019). Eco-friendly fabrication of highly selective amide-based polymer for CO2 capture. Industrial & Engineering Chemistry Research, 58(39)

- Aminu MD, Nabavi SA & Manovic V. (2018). CO2-brine-rock interactions: The effect of impurities on grain size distribution and reservoir permeability. International Journal of Greenhouse Gas Control, 78

- Fayemiwo KA, Vladisavljević GT, Nabavi SA, Benyahia B, Hanak DP, .... (2017). Nitrogen-rich hyper-crosslinked polymers for low-pressure CO2 capture. Chemical Engineering Journal, 334

- Hanak DP, Erans M, Nabavi SA, Jeremias M, Romeo LM, .... (2017). Technical and economic feasibility evaulation of calcium looping with no CO2 recirculation. Chemical Engineering Journal, 335

- Aminu MD, Nabavi SA, Rochelle CA & Manovic V. (2017). A review of developments in carbon dioxide storage. Applied Energy, 208

- Nabavi SA, Vladisavljevic GT, Zhu Y & Manovic V. (2017). Synthesis of size-tuneable CO2-philic imprinted polymeric particles (MIPs) for low-pressure CO2 capture using oil-in-oil suspension polymerisation. Environmental Science & Technology, 51(19)

- Nabavi SA, Vladisavljevic GT, Bandulasena MV, Arjmandi-Tash O & Manovic V. (2017). Prediction and control of drop formation modes in microfluidic generation of double emulsions by single-step emulsification. Journal of Colloid and Interface Science, 505

- Nabavi SA, Vladisavljevic GT & Manovic V. (2017). Mechanisms and control of single-step microfluidic generation of multi-core double emulsion droplets. Chemical Engineering Journal, 322

- Vladisavljević GT, Al Nuumani R & Nabavi SA. (2017). Microfluidic production of multiple emulsions. Micromachines, 8(3)

- Mahrukh M, Kumar A, Nabavi SA, Gu S & Sher I. (2017). Numerical analysis of the effects of using effervescent atomization on solution precursor thermal spraying process. Industrial & Engineering Chemistry Research, 56(48)

- Nabavi SA, Vladisavljevic GT, Wicaksono A, Georgiadou S & Manovic V. (2016). Production of molecularly imprinted polymer particles with amide-decorated cavities for CO2 capture using membrane emulsification/suspension polymerisation. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 521

- Nabavi SA, Vladisavljević G, Gu S & Manovic V. (2016). Semipermeable elastic microcapsules for gas capture and sensing. Langmuir, 32(38)

- Nabavi SA, Vladisavljevic GT, Eguagie E, Li B, Georgiadou S, .... (2016). Production of spherical mesoporous molecularly imprinted polymer particles containing tunable amine decorated nanocavities with CO2 molecule recognition properties. Chemical Engineering Journal, 306

- Ekanem EE, Nabavi SA, Vladisavljević GT & Gu S. (2015). Structured Biodegradable Polymeric Microparticles for Drug Delivery Produced Using Flow Focusing Glass Microfluidic Devices. ACS Applied Materials & Interfaces, 7(41)

- Nabavi SA, Gu S, Vladisavljević GT & Ekanem EE. (2015). Dynamics of double emulsion break-up in three phase glass capillary microfluidic devices. Journal of Colloid and Interface Science, 450

- Nabavi SA, Vladisavljević GT, Gu S & Ekanem EE. (2015). Double emulsion production in glass capillary microfluidic device: parametric investigation of droplet generation behaviour. Chemical Engineering Science, 130