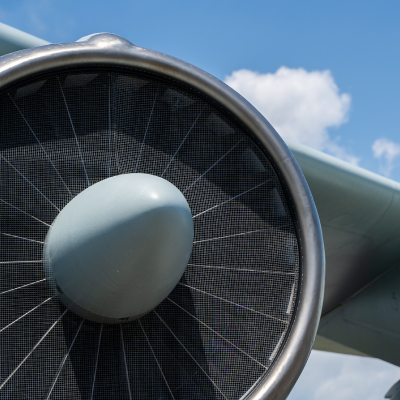

Modern aircraft design focuses on the integration of new technologies and systems with current and advanced configurations. This includes new structures, materials and manufacturing processes. The goal is to move towards environmentally-friendly and cost-effective aviation in the civil arena and high-performance and effective aviation in the military arena.

New aircraft design is essential to address issues such as carbon footprint reduction, lower noise pollution and improved passenger comfort; as well as contributing to national security.

Our work in this field covers all flying vehicles including civil and military aircraft, helicopters, Unmanned Aerial Vehicle Systems (UAVS), ultra-high capacity airlines and space vehicles.

- Advanced Configurations – such as blended wing and morphing wing aircraft design. This includes both fixed wing and rotorcraft vehicles.

- Advanced Systems Integration – such as Distributed Propulsion using hydrogen or alternative fuels for power and high temperature superconducting materials technology.

- Advanced Materials and Manufacturing Processes – exploring the benefits achieved through the application of advanced composite materials.

- Advanced Design Methodologies – developing techniques to ensure that optimum designs are achieved.

- Airworthiness Compliance – ensuring new designs demonstrate the same safety requirements as traditional aircraft.

- Operational Aspects – cost, performance, reliability and maintainability are important features of aircraft design as well as advanced techniques such as Integrated Vehicle Health Management (IVHM). Vulnerability and susceptibility also have a major impact.

- Biomimetics – taking lessons from nature for example insects and birds, and their application in aviation such as launch, recovery and flight.

Our research is sponsored by partners such as the European Union (FP7 projects) and the Engineering and Physical Sciences Research Council (EPSRC).

We work closely with air forces around the world including Canada and Nigeria.

Other industry partners include Airbus, BAE Systems, Boeing, Embraer and the Ministry of Defence.

About our research

Our greatest strength is the ability to combine the academic rigour and long-term perspective of a university with the commercial and business focus of industry.

Our excellence in strategic and applied research has enabled us to make significant contributions to the world around us for over 60 years. We address real life challenges and focus on research that is of strategic and practical importance.

We provide a supportive research community for students and our academic work is regularly published in journal article, book or thesis form.

Our facilities

We are renowned for our impressive portfolio of aerospace facilities including:

• Wind Tunnels – a number of high and low speed wind tunnels capable of investigating a wide range of different flowfields for aerodynamic testing.

• Flight Simulators – enabling the rapid reconfiguration between different aircraft types and associated systems to undertake a wide variety of research programmes in areas such as avionics, flight control systems and human factors.

• Icing Tunnel – the main tunnel is unique in the university sector and has been specifically designed to facilitate testing in SLD and fine droplet icing. The droplet tunnel is a unique vertical tunnel designed to facilitate icing phenomena at the scale of individual droplet impact events.

• Cabin Evacuation Simulators – fully reconfigurable and used to conduct research into various aspects of cabin safety.

Working with us

We have considerable expertise in aircraft design ranging from conceptual to detailed design meeting global airworthiness requirements. Our multi-disciplinary teams are able to respond quickly to design requirements, providing solutions in the form of hardware and flying demonstrators. Major design aspects are considered including susceptibility, vulnerability, reliability, maintainability and operational cost.

Industry values our recommendations and we been invited to undertake independent reviews of aircraft design for manufacturers. Client confidentiality is treated with the utmost importance and some members of our academic team have national security clearance.