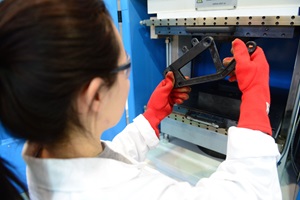

An extensive range of facilities underpins the work of the Centre including our state-of-the-art laboratory where we undertake composites manufacturing related research. Our facilities allow us to provide tailored solutions to a variety of problems involving composite structural design and manufacture. We can provide concept design, modelling and test capabilities from preliminary to detailed (TRL1 to TRL6).

General equipment includes:

- Pilot scale composites manufacturing equipment including autoclave, RTM, infusion, press moulding;

- Various NDI capabilities;

- Aircrafts wing structure demonstrators;

- Thermal and thermo-mechanical analysis suite including DSC, DMA, TMA;

- Rheological analysis suite;

- Dielectric cure monitoring suite;

- Fibre optic monitoring systems;

- Mechanical testing lab including conditioning chambers, infrared/high speed imaging cameras, digital image correlation systems and phased array ultrasonics;

- Microscopy and surface characterisation suite;

- Robotic tufting set up;

- Ultrasonic z-pinning hammer;

- In-house codes for variability analysis;

- Standard non-linear FE packages for coupled thermo-mechanical analysis.

A selection list of manufacturing and characterisation facilities at the centre is shown below.

|

Vacuum assisted oven - CALTHERM 2m x 1m x 1m oven 200°C |

|

400°C press, 420mm platterns |

|

Air press vacuum forming table, upper infrared heater |

|

20 ton hand-operated hydraulic press |

|

Isojet piston RTM machine |

|

Mini RTM mould tool 2-6mm cavity |

|

KSL tufting sewing head |

|

7 axis robot Kawasaki |

|

MP19 laboratory twin screw extruder |

|

Q200 MDSC mass flow control |

|

Instrumented static, dynamic, fatigue and impact mechanical testing facilities |

|

Vacuum assisted oven |

|

Six axis robotic arm |

|

Autoclave |

|

|

Compression mould, fontune presses machine |

|

EXPERT® process system press |